Page 467 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 467

Theory of Constraints 425

The theory of constraints also believes that the balanced capacity may not

be a good approach for maintaining high throughput. The most important

issue is to balance flow. This is illustrated by Example 12.4.

Example 12.4: Capacity Balance versus Flow Balance

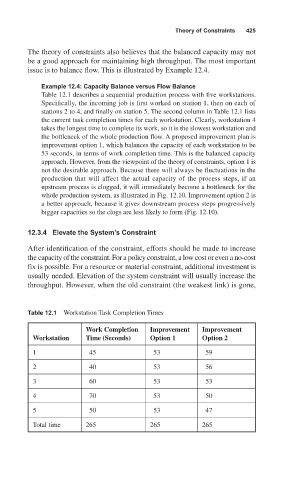

Table 12.1 describes a sequential production process with five workstations.

Specifically, the incoming job is first worked on station 1, then on each of

stations 2 to 4, and finally on station 5. The second column in Table 12.1 lists

the current task completion times for each workstation. Clearly, workstation 4

takes the longest time to complete its work, so it is the slowest workstation and

the bottleneck of the whole production flow. A proposed improvement plan is

improvement option 1, which balances the capacity of each workstation to be

53 seconds, in terms of work completion time. This is the balanced capacity

approach. However, from the viewpoint of the theory of constraints, option 1 is

not the desirable approach. Because there will always be fluctuations in the

production that will affect the actual capacity of the process steps, if an

upstream process is clogged, it will immediately become a bottleneck for the

whole production system, as illustrated in Fig. 12.10. Improvement option 2 is

a better approach, because it gives downstream process steps progressively

bigger capacities so the clogs are less likely to form (Fig. 12.10).

12.3.4 Elevate the System’s Constraint

After identification of the constraint, efforts should be made to increase

the capacity of the constraint. For a policy constraint, a low cost or even a no-cost

fix is possible. For a resource or material constraint, additional investment is

usually needed. Elevation of the system constraint will usually increase the

throughput. However, when the old constraint (the weakest link) is gone,

Table 12.1 Workstation Task Completion Times

Work Completion Improvement Improvement

Workstation Time (Seconds) Option 1 Option 2

1 45 53 59

2 40 53 56

3 60 53 53

4 70 53 50

5 50 53 47

Total time 265 265 265