Page 69 - Design of Reinforced Masonry Structures

P. 69

2.22 CHAPTER TWO

shall be of whole, sound materials and free from cracks and other defects that will interfere

with proper laying or use. Old mortar shall be cleaned from the units before reuse.” The

MSJC-08 Code [2.43] apparently does not permit the use of salvaged brick units. MSJC

Specification for Masonry Structures [2.4, Section 2.3B] requires clay or shale masonry

units to conform to following ASTM Standards as specified:

1. ASTM C34-03: Specification for Structural Clay Load-Bearing Wall Tile [2.22].

2. ASTM C56-05: Specification for Structural Clay Nonload-Bearing Structural Wall

Tile [2.23].

3. ASTM C62-05: Specification for Building Brick (Solid Masonry Units Made from

Clay or Shale [2.12].

4. ASTM C126-99 (2005): Specification for Ceramic Glazed Structural Clay Facing

Tile, Facing Brick, and Solid Masonry Units [2.17].

5. ASTM C212-00: Specification for Structural Clay Facing Tile [2.37].

6. ASTM C216-05a: Specification for Building Brick (Solid Masonry Units Made from

Clay or Shale [2.14].

7. ASTM C652-05a: Specification for Hollow Brick (Hollow Masonry Units Made from

Clay or Shale).

8. ASTM C1088-02: Specification for Thin Veneer Brick Units Made form Clay or

Shale [2.18].

9. ASTM C1405-05a: Specification for Glazed Brick (single fired brick).

Or to

ANSI A137.1-88: Standard Specification for Ceramic Tile [2.41].

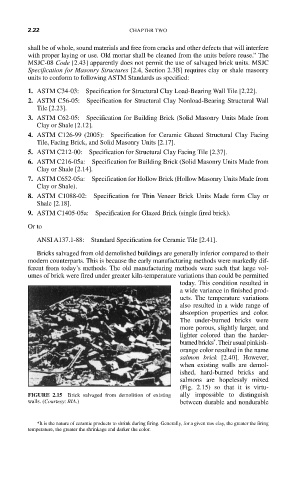

Bricks salvaged from old demolished buildings are generally inferior compared to their

modern counterparts. This is because the early manufacturing methods were markedly dif-

ferent from today’s methods. The old manufacturing methods were such that large vol-

umes of brick were fired under greater kiln-temperature variations than could be permitted

today. This condition resulted in

a wide variance in finished prod-

ucts. The temperature variations

also resulted in a wide range of

absorption properties and color.

The under-burned bricks were

more porous, slightly larger, and

lighter colored than the harder-

*

burned bricks . Their usual pinkish-

orange color resulted in the name

salmon brick [2.40]. However,

when existing walls are demol-

ished, hard-burned bricks and

salmons are hopelessly mixed

(Fig. 2.15) so that it is virtu-

FIGURE 2.15 Brick salvaged from demolition of existing ally impossible to distinguish

walls. (Courtesy: BIA.) between durable and nondurable

*It is the nature of ceramic products to shrink during firing. Generally, for a given raw clay, the greater the firing

temperature, the greater the shrinkage and darker the color.