Page 94 - Design of Reinforced Masonry Structures

P. 94

2.46 CHAPTER TWO

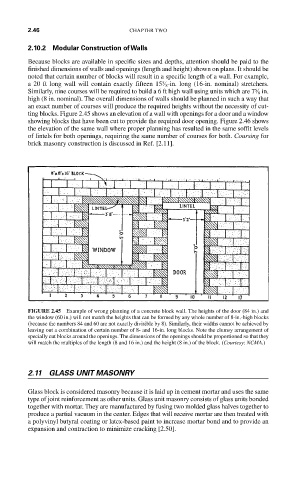

2.10.2 Modular Construction of Walls

Because blocks are available in specific sizes and depths, attention should be paid to the

finished dimensions of walls and openings (length and height) shown on plans. It should be

noted that certain number of blocks will result in a specific length of a wall. For example,

5

a 20 ft long wall will contain exactly fifteen 15 ⁄ 8-in. long (16-in. nominal) stretchers.

5

Similarly, nine courses will be required to build a 6 ft high wall using units which are 7 ⁄ 8 in.

high (8 in. nominal). The overall dimensions of walls should be planned in such a way that

an exact number of courses will produce the required heights without the necessity of cut-

ting blocks. Figure 2.45 shows an elevation of a wall with openings for a door and a window

showing blocks that have been cut to provide the required door opening. Figure 2.46 shows

the elevation of the same wall where proper planning has resulted in the same soffit levels

of lintels for both openings, requiring the same number of courses for both. Coursing for

brick masonry construction is discussed in Ref. [2.11].

FIGURE 2.45 Example of wrong planning of a concrete block wall. The heights of the door (84 in.) and

the window (60 in.) will not match the heights that can be formed by any whole number of 8-in.-high blocks

(because the numbers 84 and 60 are not exactly divisible by 8). Similarly, their widths cannot be achieved by

leaving out a combination of certain number of 8- and 16-in. long blocks. Note the clumsy arrangement of

specially cut blocks around the openings. The dimensions of the openings should be proportioned so that they

will match the multiples of the length (8 and 16 in.) and the height (8 in.) of the block. (Courtesy: NCMA.)

2.11 GLASS UNIT MASONRY

Glass block is considered masonry because it is laid up in cement mortar and uses the same

type of joint reinforcement as other units. Glass unit masonry consists of glass units bonded

together with mortar. They are manufactured by fusing two molded glass halves together to

produce a partial vacuum in the center. Edges that will receive mortar are then treated with

a polyvinyl butyral coating or latex-based paint to increase mortar bond and to provide an

expansion and contraction to minimize cracking [2.50].