Page 193 - Design of Simple and Robust Process Plants

P. 193

178 Chapter 5 Process Simplification and Intensification Techniques

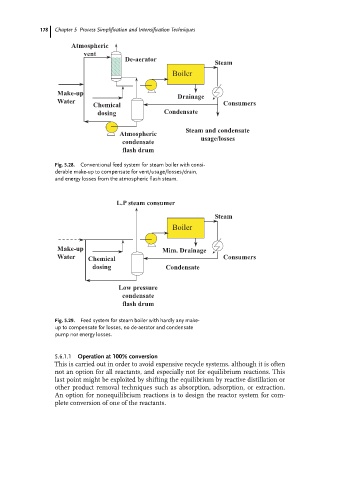

Atmospheric

vent

De-aerator

Steam

Boiler

Make-up

Drainage

Water Consumers

Chemical

dosing Condensate

Steam and condensate

Atmospheric

usage/losses

condensate

flash drum

Fig. 5.28. Conventional feed system for steam boiler with consi-

derable make-up to compensate for vent/usage/losses/drain,

and energy losses from the atmospheric flash steam.

L.P steam consumer

Steam

Boiler

Make-up Mim. Drainage

Water Chemical Consumers

dosing Condensate

Low pressure

condensate

flash drum

Fig. 5.29. Feed system for steam boiler with hardly any make-

up to compensate for losses, no de-aerator and condensate

pump nor energy losses.

5.6.1.1 Operation at 100% conversion

This is carried out in order to avoid expensive recycle systems. although it is often

not an option for all reactants, and especially not for equilibrium reactions. This

last point might be exploited by shifting the equilibrium by reactive distillation or

other product removal techniques such as absorption, adsorption, or extraction.

An option for nonequilibrium reactions is to design the reactor system for com-

plete conversion of one of the reactants.