Page 257 - Design of Simple and Robust Process Plants

P. 257

6.4 Application of Reliability Studies for a Process and Utility Plant 243

Case 3 Case4

100 t/hr

Boil 1

253 t/hr

100 t/hr New

Boil 2 boiler 253 t/hr

253 t/hr

150 t/hr New

boiler

New 253 t/hr

boiler

253 t/hr

150 t/hr New

boiler

New

boiler 253 t/hr

253 t/hr

150 t/hr New

boiler

New

boiler

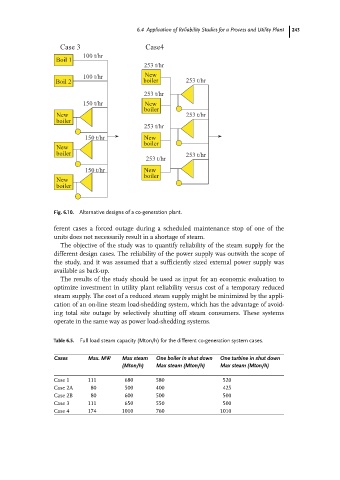

Fig. 6.10. Alternative designs of a co-generation plant.

ferent cases a forced outage during a scheduled maintenance stop of one of the

units does not necessarily result in a shortage of steam.

The objective of the study was to quantify reliability of the steam supply for the

different design cases. The reliability of the power supply was outwith the scope of

the study, and it was assumed that a sufficiently sized external power supply was

available as back-up.

The results of the study should be used as input for an economic evaluation to

optimize investment in utility plant reliability versus cost of a temporary reduced

steam supply. The cost of a reduced steam supply might be minimized by the appli-

cation of an on-line steam load-shedding system, which has the advantage of avoid-

ing total site outage by selectively shutting off steam consumers. These systems

operate in the same way as power load-shedding systems.

Table 6.5. Full load steam capacity (Mton/h) for the different co-generation system cases.

Cases Max. MW Max steam One boiler in shut down One turbine in shut down

(Mton/h) Max steam (Mton/h) Max steam (Mton/h)

Case 1 111 680 580 520

Case 2A 80 500 400 425

Case 2B 80 600 500 500

Case 3 111 650 550 500

Case 4 174 1010 760 1010