Page 275 - Design of Simple and Robust Process Plants

P. 275

7.5 The Optimization of an Integrated Complex 261

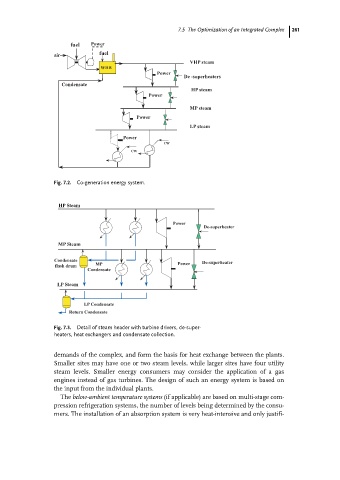

fuel Power

air fuel

VHP steam

WHB

Power

De -superheaters

Condensate

HP steam

Power

MP steam

Power

LP steam

Power

CW

CW

Fig. 7.2. Co-generation energy system.

HP Steam

Power

De-superheater

MP Steam

Condensate De-superheater

flash drum MP Power

Condensate

LP Steam

LP Condensate

Return Condensate

Fig. 7.3. Detail of steam header with turbine drivers, de-super-

heaters, heat exchangers and condensate collection.

demands of the complex, and form the basis for heat exchange between the plants.

Smaller sites may have one or two steam levels, while larger sites have four utility

steam levels. Smaller energy consumers may consider the application of a gas

engines instead of gas turbines. The design of such an energy system is based on

the input from the individual plants.

The below-ambient temperature systems (if applicable) are based on multi-stage com-

pression refrigeration systems, the number of levels being determined by the consu-

mers. The installation of an absorption system is very heat-intensive and only justifi-