Page 35 - Design of Simple and Robust Process Plants

P. 35

18 Chapter 1 Introduction

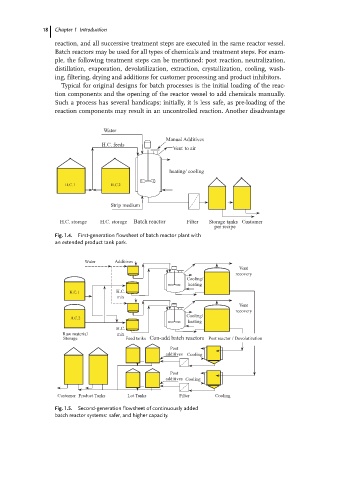

reaction, and all successive treatment steps are executed in the same reactor vessel.

Batch reactors may be used for all types of chemicals and treatment steps. For exam-

ple, the following treatment steps can be mentioned: post reaction, neutralization,

distillation, evaporation, devolatilization, extraction, crystallization, cooling, wash-

ing, filtering, drying and additions for customer processing and product inhibitors.

Typical for original designs for batch processes is the initial loading of the reac-

tion components and the opening of the reactor vessel to add chemicals manually.

Such a process has several handicaps; initially, it is less safe, as pre-loading of the

reaction components may result in an uncontrolled reaction. Another disadvantage

Water

Manual Additives

H.C. feeds

Vent to air

heating/ cooling

H.C.1 H.C.2

Strip medium

H.C. storage H.C. storage Batch reactor Filter Storage tanks Customer

per recipe

Fig. 1.4. First-generation flowsheet of batch reactor plant with

an extended product tank park.

Water Additives

Vent

recovery

Cooling/

heating

H.C.1 H.C.

mix

Vent

recovery

Cooling/

H.C.2

heating

H.C.

Raw material mix

Storage Feed tanks Con-add batch reactors Post reactor / Devolatization

Post

additives Cooling

Post

additives Cooling

Customer Product Tanks Lot Tanks Filter Cooling

Fig. 1.5. Second-generation flowsheet of continuously added

batch reactor systems: safer, and higher capacity.