Page 356 - Design of Simple and Robust Process Plants

P. 356

342 Chapter 8 Instrumentation, Automation of Operation and Control

its constraints, and its predictions. Despite these limitations, they have found wide

acceptance for predictive and constraint control, and have obtained a solid position

in the operational pyramid (see Figure 8.1).

The above does not limit the model-based control layer from performing some

elementary calculations to support control, without compromising on robustness.

Model-based control at the basic control layer must be restricted in order to

achieve the required level of robustness. These restrictions within the current state

of the technology are:

. Apply algebraic equations which make solving a straightforward exercise.

. Avoid optimization and iterations ± a straightforward answer is not guaran-

teed.

. Avoid constraint control ± constraints are always difficult to model.

. Avoid predictive action, as these introduce a level of uncertainty

The models are preferably derived from fundamental models, including mass and

energy balances which have a wide application area.

With the above restrictions in mind, there are still many opportunities for applica-

tions. The applications of ratio controller or feed-forward controller provided with

corrections for response times are the most elementary. The design of a controller

based on heat balances (as applied in Figure 4.29 in Chapter 4) is a simple example.

A more pronounced application of the development of model-based control at the

basic control layer is published by Verwijs (2001) and is described below.

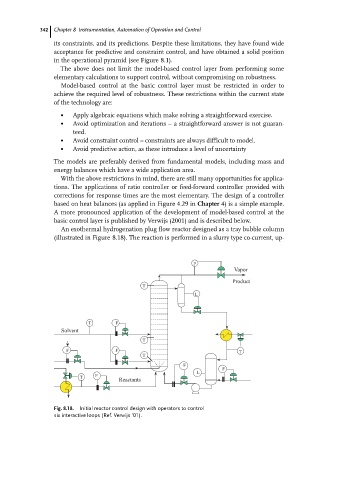

An exothermal hydrogenation plug flow reactor designed as a tray bubble column

(illustrated in Figure 8.18). The reaction is performed in a slurry type co-current, up-

P

Vapor

Product

T

L

T F

Solvent

T

F F T

T

F

F

L

F

T

Reactants

Fig. 8.18. Initial reactor control design with operators to control

six interactive loops (Ref. Verwijs '01).