Page 391 - Design of Simple and Robust Process Plants

P. 391

378 Chapter 9 Operation Optimization

9.6

Project Methodology for Operation Optimization

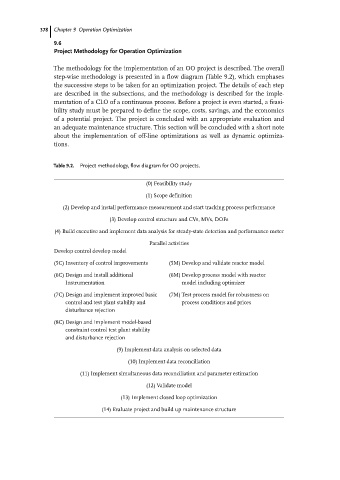

The methodology for the implementation of an OO project is described. The overall

step-wise methodology is presented in a flow diagram (Table 9.2), which emphases

the successive steps to be taken for an optimization project. The details of each step

are described in the subsections, and the methodology is described for the imple-

mentation of a CLO of a continuous process. Before a project is even started, a feasi-

bility study must be prepared to define the scope, costs, savings, and the economics

of a potential project. The project is concluded with an appropriate evaluation and

an adequate maintenance structure. This section will be concluded with a short note

about the implementation of off-line optimizations as well as dynamic optimiza-

tions.

Table 9.2. Project methodology, flow diagram for OO projects.

(0)Feasibility study

(1)Scope definition

(2)Develop and install performance measurement and start tracking process performance

(3)Develop control structure and CVs, MVs, DOFs

(4)Build executive and implement data analysis for steady-state detection and performance meter

Parallel activities

Develop control develop model

(5C)Inventory of control improvements (5M)Develop and validate reactor model

(6C)Design and install additional (6M)Develop process model with reactor

Instrumentation model including optimizer

(7C)Design and implement improved basic (7M)Test process model for robustness on

control and test plant stability and process conditions and prices

disturbance rejection

(8C)Design and implement model-based

constraint control test plant stability

and disturbance rejection

(9)Implement data analysis on selected data

(10)Implement data reconciliation

(11)Implement simultaneous data reconciliation and parameter estimation

(12)Validate model

(13)Implement closed loop optimization

(14)Evaluate project and build up maintenance structure