Page 342 - Distillation theory

P. 342

P1: JPJ/FFX P2: FCH/FFX QC: FCH/FFX T1: FCH

0521820928c08 CB644-Petlyuk-v1 June 11, 2004 20:20

316 Synthesis of Separation Flowsheets

D

M 1

a) b)

D st M 2

M 1

st M 3

M 2

st M 4

F F

st B st B

D 2

c)

D 1

st M 1

st

st M 2

F

st B 1 st B 2

D 1 D 2

d)

st st

M 1 M 3

st st

M 2 M 4

F

st st B 2

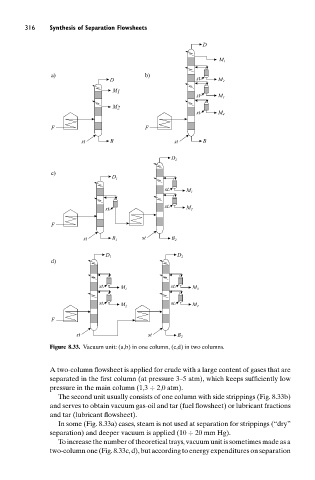

Figure 8.33. Vacuum unit: (a,b) in one column, (c,d) in two columns.

A two-column flowsheet is applied for crude with a large content of gases that are

separated in the first column (at pressure 3–5 atm), which keeps sufficiently low

pressure in the main column (1,3 ÷ 2,0 atm).

The second unit usually consists of one column with side strippings (Fig. 8.33b)

and serves to obtain vacuum gas-oil and tar (fuel flowsheet) or lubricant fractions

and tar (lubricant flowsheet).

In some (Fig. 8.33a) cases, steam is not used at separation for strippings (“dry”

separation) and deeper vacuum is applied (10 ÷ 20 mm Hg).

To increase the number of theoretical trays, vacuum unit is sometimes made as a

two-columnone(Fig.8.33c,d),butaccordingtoenergyexpendituresonseparation