Page 52 - Drilling Technology in Nontechnical Language

P. 52

Chapter 3 – DRILLING A LAND EXPLORATION WELL 43

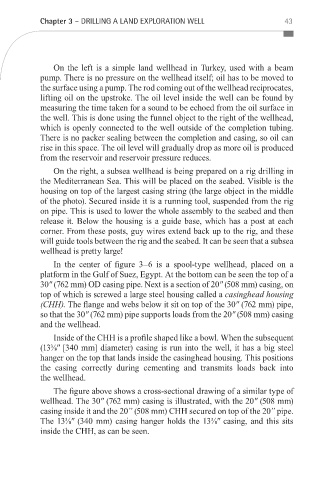

On the left is a simple land wellhead in Turkey, used with a beam

pump. There is no pressure on the wellhead itself; oil has to be moved to

the surface using a pump. The rod coming out of the wellhead reciprocates,

lifting oil on the upstroke. The oil level inside the well can be found by

measuring the time taken for a sound to be echoed from the oil surface in

the well. This is done using the funnel object to the right of the wellhead,

which is openly connected to the well outside of the completion tubing.

There is no packer sealing between the completion and casing, so oil can

rise in this space. The oil level will gradually drop as more oil is produced

from the reservoir and reservoir pressure reduces.

On the right, a subsea wellhead is being prepared on a rig drilling in

the Mediterranean Sea. This will be placed on the seabed. Visible is the

housing on top of the largest casing string (the large object in the middle

of the photo). Secured inside it is a running tool, suspended from the rig

on pipe. This is used to lower the whole assembly to the seabed and then

release it. Below the housing is a guide base, which has a post at each

corner. From these posts, guy wires extend back up to the rig, and these

will guide tools between the rig and the seabed. It can be seen that a subsea

wellhead is pretty large!

In the center of figure 3–6 is a spool-type wellhead, placed on a

platform in the Gulf of Suez, Egypt. At the bottom can be seen the top of a

30" (762 mm) OD casing pipe. Next is a section of 20" (508 mm) casing, on

top of which is screwed a large steel housing called a casinghead housing

(CHH). The flange and webs below it sit on top of the 30" (762 mm) pipe,

so that the 30" (762 mm) pipe supports loads from the 20" (508 mm) casing

and the wellhead.

Inside of the CHH is a profile shaped like a bowl. When the subsequent

(13⅜″ [340 mm] diameter) casing is run into the well, it has a big steel

hanger on the top that lands inside the casinghead housing. This positions

the casing correctly during cementing and transmits loads back into

the wellhead.

The figure above shows a cross-sectional drawing of a similar type of

wellhead. The 30″ (762 mm) casing is illustrated, with the 20″ (508 mm)

casing inside it and the 20” (508 mm) CHH secured on top of the 20” pipe.

The 13⅜″ (340 mm) casing hanger holds the 13⅜″ casing, and this sits

inside the CHH, as can be seen.

_Devereux_Book.indb 43 1/16/12 2:06 PM