Page 53 - Drilling Technology in Nontechnical Language

P. 53

44 Drilling Technology in Nontechnical Language Second Edition

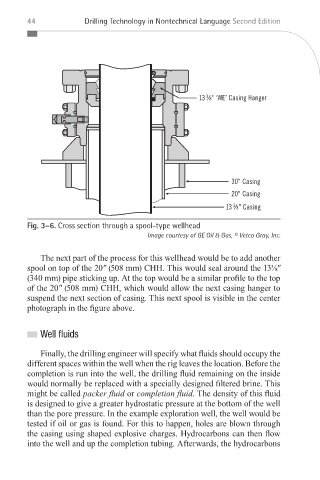

Fig. 3–6. Cross section through a spool-type wellhead

Image courtesy of GE Oil & Gas, © Vetco Gray, Inc.

The next part of the process for this wellhead would be to add another

spool on top of the 20" (508 mm) CHH. This would seal around the 13⅜"

(340 mm) pipe sticking up. At the top would be a similar profile to the top

of the 20" (508 mm) CHH, which would allow the next casing hanger to

suspend the next section of casing. This next spool is visible in the center

photograph in the figure above.

Well uids

Finally, the drilling engineer will specify what fluids should occupy the

different spaces within the well when the rig leaves the location. Before the

completion is run into the well, the drilling fluid remaining on the inside

would normally be replaced with a specially designed filtered brine. This

might be called packer fl uid or completion fl uid. The density of this fluid

is designed to give a greater hydrostatic pressure at the bottom of the well

than the pore pressure. In the example exploration well, the well would be

tested if oil or gas is found. For this to happen, holes are blown through

the casing using shaped explosive charges. Hydrocarbons can then flow

into the well and up the completion tubing. Afterwards, the hydrocarbons

_Devereux_Book.indb 44 1/16/12 2:06 PM