Page 150 - Drilling Technology in Nontechnical Language

P. 150

6

DRILL BITS

Overview

This chapter will describe the basic classifications of drill bits and the

major design features of each type. The process of bit selection, which is

actually quite complicated if done properly, will be outlined in sufficient

detail to show the main considerations involved. It will hopefully give an

accurate impression of the complexity of bit selection and how critical this

is to operational economics.

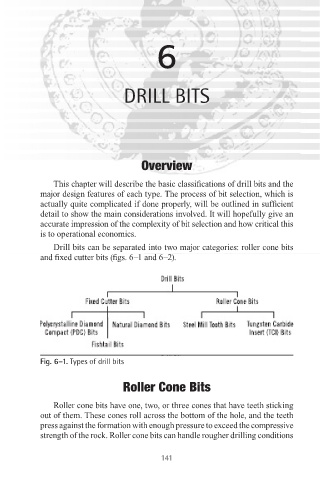

Drill bits can be separated into two major categories: roller cone bits

and fixed cutter bits (figs. 6–1 and 6–2).

Fig. 6–1. Types of drill bits

Roller Cone Bits

Roller cone bits have one, two, or three cones that have teeth sticking

out of them. These cones roll across the bottom of the hole, and the teeth

press against the formation with enough pressure to exceed the compressive

strength of the rock. Roller cone bits can handle rougher drilling conditions

141

_Devereux_Book.indb 141 1/16/12 2:09 PM