Page 147 - Drilling Technology in Nontechnical Language

P. 147

138 Drilling Technology in Nontechnical Language Second Edition

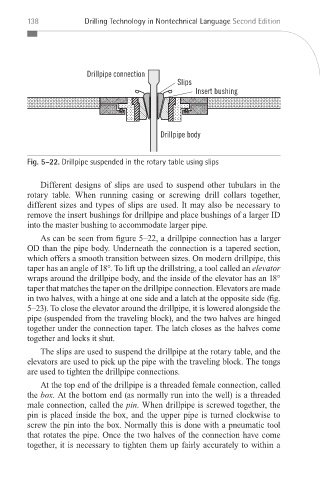

Fig. 5–22. Drillpipe suspended in the rotary table using slips

Different designs of slips are used to suspend other tubulars in the

rotary table. When running casing or screwing drill collars together,

different sizes and types of slips are used. It may also be necessary to

remove the insert bushings for drillpipe and place bushings of a larger ID

into the master bushing to accommodate larger pipe.

As can be seen from figure 5–22, a drillpipe connection has a larger

OD than the pipe body. Underneath the connection is a tapered section,

which offers a smooth transition between sizes. On modern drillpipe, this

taper has an angle of 18°. To lift up the drillstring, a tool called an elevator

wraps around the drillpipe body, and the inside of the elevator has an 18°

taper that matches the taper on the drillpipe connection. Elevators are made

in two halves, with a hinge at one side and a latch at the opposite side (fig.

5–23). To close the elevator around the drillpipe, it is lowered alongside the

pipe (suspended from the traveling block), and the two halves are hinged

together under the connection taper. The latch closes as the halves come

together and locks it shut.

The slips are used to suspend the drillpipe at the rotary table, and the

elevators are used to pick up the pipe with the traveling block. The tongs

are used to tighten the drillpipe connections.

At the top end of the drillpipe is a threaded female connection, called

the box. At the bottom end (as normally run into the well) is a threaded

male connection, called the pin. When drillpipe is screwed together, the

pin is placed inside the box, and the upper pipe is turned clockwise to

screw the pin into the box. Normally this is done with a pneumatic tool

that rotates the pipe. Once the two halves of the connection have come

together, it is necessary to tighten them up fairly accurately to within a

_Devereux_Book.indb 138 1/16/12 2:09 PM