Page 185 - Drilling Technology in Nontechnical Language

P. 185

176 Drilling Technology in Nontechnical Language Second Edition

It is now the job of the drilling engineer to look at the possible surface

locations (there may or may not be a choice about this) and then design a

well path to meet the target requirements at the lowest cost. Some flexibility

as to the surface location (such as a desert or offshore when drilling straight

into the seabed) can be a great help in minimizing cost.

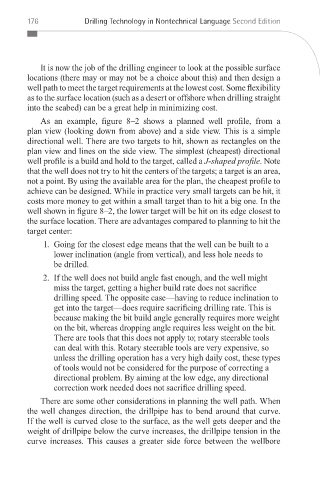

As an example, figure 8–2 shows a planned well profile, from a

plan view (looking down from above) and a side view. This is a simple

directional well. There are two targets to hit, shown as rectangles on the

plan view and lines on the side view. The simplest (cheapest) directional

well profile is a build and hold to the target, called a J-shaped profile. Note

that the well does not try to hit the centers of the targets; a target is an area,

not a point. By using the available area for the plan, the cheapest profile to

achieve can be designed. While in practice very small targets can be hit, it

costs more money to get within a small target than to hit a big one. In the

well shown in figure 8–2, the lower target will be hit on its edge closest to

the surface location. There are advantages compared to planning to hit the

target center:

1. Going for the closest edge means that the well can be built to a

lower inclination (angle from vertical), and less hole needs to

be drilled.

2. If the well does not build angle fast enough, and the well might

miss the target, getting a higher build rate does not sacrifice

drilling speed. The opposite case—having to reduce inclination to

get into the target—does require sacrificing drilling rate. This is

because making the bit build angle generally requires more weight

on the bit, whereas dropping angle requires less weight on the bit.

There are tools that this does not apply to; rotary steerable tools

can deal with this. Rotary steerable tools are very expensive, so

unless the drilling operation has a very high daily cost, these types

of tools would not be considered for the purpose of correcting a

directional problem. By aiming at the low edge, any directional

correction work needed does not sacrifice drilling speed.

There are some other considerations in planning the well path. When

the well changes direction, the drillpipe has to bend around that curve.

If the well is curved close to the surface, as the well gets deeper and the

weight of drillpipe below the curve increases, the drillpipe tension in the

curve increases. This causes a greater side force between the wellbore

_Devereux_Book.indb 176 1/16/12 2:10 PM