Page 193 - Drilling Technology in Nontechnical Language

P. 193

184 Drilling Technology in Nontechnical Language Second Edition

Stabilizers are positioned so that drill collar sag tends to push the bit

into the low side of the hole or to push the bit up to the high side of the hole,

or to have very little or no side force. This is achieved by selecting both the

positions of the stabilizers and whether the stabilizers are the same size as

the drill bit (full gauge) or smaller (undergauge).

For a rotary build assembly to work, the hole needs some inclination

(over about 12°) to create the sag. The higher the inclination, the more

side force is generated with a particular rotary build assembly. The near

bit stabilizer (NB stab) acts as a fulcrum, so the drill collars above can be

thought of like a lever—push down on the upper part of the lever, and the

opposite side pushes up. If the NB stab is undergauge, it will develop less

upwards side force, and so the stabilizer gauge has an effect. If the next

stabilizer up is (or becomes) undergauge, this will increase the build effect

because the upper part of the lever will be moved downwards.

The weight applied to the bit also has a large effect. With sag in the

drill collars, applying weight from above will increase the level of sag as

the drill collar starts to buckle. Therefore the more weight that is applied

to a build assembly, the faster it will build.

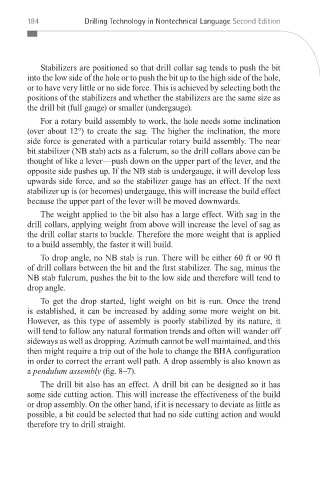

To drop angle, no NB stab is run. There will be either 60 ft or 90 ft

of drill collars between the bit and the first stabilizer. The sag, minus the

NB stab fulcrum, pushes the bit to the low side and therefore will tend to

drop angle.

To get the drop started, light weight on bit is run. Once the trend

is established, it can be increased by adding some more weight on bit.

However, as this type of assembly is poorly stabilized by its nature, it

will tend to follow any natural formation trends and often will wander off

sideways as well as dropping. Azimuth cannot be well maintained, and this

then might require a trip out of the hole to change the BHA configuration

in order to correct the errant well path. A drop assembly is also known as

a pendulum assembly (fig. 8–7).

The drill bit also has an effect. A drill bit can be designed so it has

some side cutting action. This will increase the effectiveness of the build

or drop assembly. On the other hand, if it is necessary to deviate as little as

possible, a bit could be selected that had no side cutting action and would

therefore try to drill straight.

_Devereux_Book.indb 184 1/16/12 2:11 PM