Page 196 - Drilling Technology in Nontechnical Language

P. 196

Chapter 8 – DIRECTIONAL AND HORIZONTAL DRILLING 187

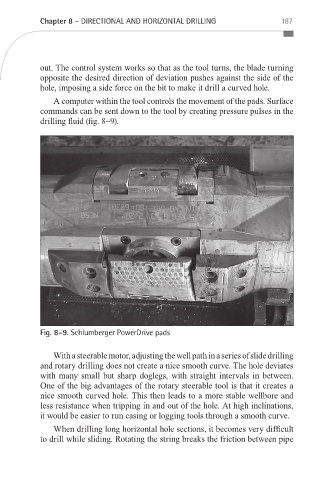

out. The control system works so that as the tool turns, the blade turning

opposite the desired direction of deviation pushes against the side of the

hole, imposing a side force on the bit to make it drill a curved hole.

A computer within the tool controls the movement of the pads. Surface

commands can be sent down to the tool by creating pressure pulses in the

drilling fluid (fig. 8–9).

Fig. 8–9. Schlumberger PowerDrive pads

With a steerable motor, adjusting the well path in a series of slide drilling

and rotary drilling does not create a nice smooth curve. The hole deviates

with many small but sharp doglegs, with straight intervals in between.

One of the big advantages of the rotary steerable tool is that it creates a

nice smooth curved hole. This then leads to a more stable wellbore and

less resistance when tripping in and out of the hole. At high inclinations,

it would be easier to run casing or logging tools through a smooth curve.

When drilling long horizontal hole sections, it becomes very difficult

to drill while sliding. Rotating the string breaks the friction between pipe

_Devereux_Book.indb 187 1/16/12 2:11 PM