Page 210 - Drilling Technology in Nontechnical Language

P. 210

Chapter 9 – CASING AND CEMENTING 201

▪ Utility. The inside diameter of the liner is inevitably less than the

ID of the production casing. This allows tools to be run as part of

the completion that would be too large to fit inside the liner but

that could be set higher up, inside the casing.

Disadvantages to liners include the following:

▪ Complexity. The equipment required to run a liner is much more

complex than for a casing, so there is more chance that something

will go wrong.

▪ Obtaining a good cement job. Cement volumes tend to be pretty

small around liners, so a bit of contamination of the slurry by

drilling mud will go a lot further. This was one of the issues with

the Deepwater Horizon blowout in the Gulf of Mexico.

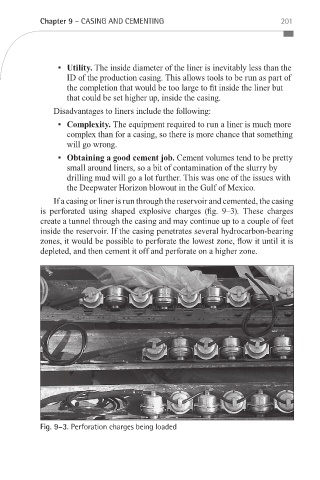

If a casing or liner is run through the reservoir and cemented, the casing

is perforated using shaped explosive charges (fig. 9–3). These charges

create a tunnel through the casing and may continue up to a couple of feet

inside the reservoir. If the casing penetrates several hydrocarbon-bearing

zones, it would be possible to perforate the lowest zone, flow it until it is

depleted, and then cement it off and perforate on a higher zone.

Fig. 9–3. Perforation charges being loaded

_Devereux_Book.indb 201 1/16/12 2:11 PM