Page 76 - Drilling Technology in Nontechnical Language

P. 76

Chapter 3 – DRILLING A LAND EXPLORATION WELL 67

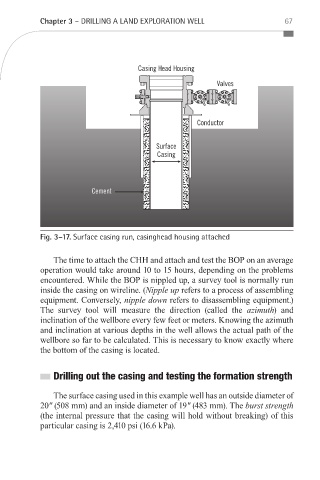

Fig. 3–17. Surface casing run, casinghead housing attached

The time to attach the CHH and attach and test the BOP on an average

operation would take around 10 to 15 hours, depending on the problems

encountered. While the BOP is nippled up, a survey tool is normally run

inside the casing on wireline. (Nipple up refers to a process of assembling

equipment. Conversely, nipple down refers to disassembling equipment.)

The survey tool will measure the direction (called the azimuth) and

inclination of the wellbore every few feet or meters. Knowing the azimuth

and inclination at various depths in the well allows the actual path of the

wellbore so far to be calculated. This is necessary to know exactly where

the bottom of the casing is located.

Drilling out the casing and testing the formation strength

The surface casing used in this example well has an outside diameter of

20" (508 mm) and an inside diameter of 19" (483 mm). The burst strength

(the internal pressure that the casing will hold without breaking) of this

particular casing is 2,410 psi (16.6 kPa).

_Devereux_Book.indb 67 1/16/12 2:06 PM