Page 143 - Dust Explosions in the Process Industries

P. 143

1 16 Dust Explosions in the Process Industries

In the case of products that are fine in themselves, such as wheat flour and tapioca, oil

addition for suppressing dust is less suitable than in the case of a coarse main product

containing a small dust fraction. However, in some cases, circumstancespermit addition

of larger amounts of oil, up to several percent, which can give a significant reduction of

dust emission even for such fine products.

1.4.11

CONSTRUCTION AND LAYOUT OF BUILDINGS

It is important to distinguishbetween ideal requirements and realistic possibilities.In all

circumstances,it is stronglyrecommendedthat the dust explosionproblem be taken into

account as early as possible in the planning process, whether a completely new plant is

to be constructed or an existing plant rebuilt.

Ideally, any factory in which dust explosions may occur should be located a safe dis-

tance from other buildings. Furthermore, the various parts of the factory should be sep-

arate to enable effective isolation of the explosion to the section of the factory where it

starts.

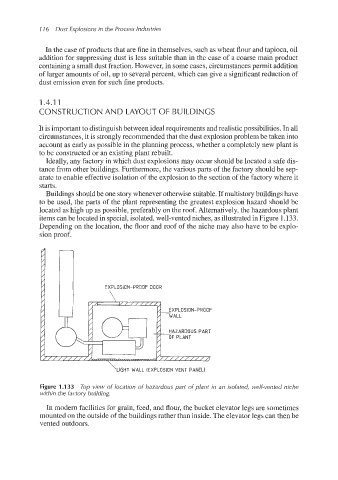

Buildings should be one story whenever otherwisesuitable.If multistory buildings have

to be used, the parts of the plant representing the greatest explosion hazard should be

located as high up as possible, preferably on the roof. Alternatively, the hazardous plant

items can be locatedin special, isolated,well-vented niches, as illustrated in Figure 1.133.

Depending on the location, the floor and roof of the niche may also have to be explo-

sion proof.

EXPLOSION-PROOF DOOR

\

XPLOSION-PROOF

AZARDOUS PART

‘LIGHT WALL (EXPLOSION VENT PANEL)

Figure 1.133 Top view of location of hazardous part of plant in an isolated, well-vented niche

within the factory building.

In modern facilities for grain, feed, and flour, the bucket elevator legs are sometimes

mounted on the outside of the buildings rather than inside. The elevator legs can then be

vented outdoors.