Page 138 - Dust Explosions in the Process Industries

P. 138

Dust Explosions:An Overview 7 7 7

PASSIVE EXPLOSION

INTERRUPTER

-

--CHIMNEY

D

FRESH GAS

DRYING

Q-RECYCLE€! GAS FOR DRYING

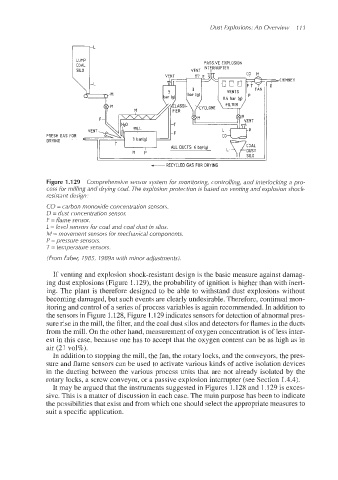

Figure 1.1 29 Comprehensive sensor system for monitoring, controlling, and interlocking a pro-

cess for milling and drying coal. The explosion protection is based on venting and explosion shock-

resistant design:

CO = carbon monoxide concentration sensors.

D = dust concentration sensor.

F = flame sensor.

L = level sensors for coal and coal dust in silos.

M = movement sensors for mechanical components.

P = pressure sensors.

T = temperature sensors.

(From Faber, 1985, 1989a with minor adjustments).

If venting and explosion shock-resistant design is the basic measure against damag-

ing dust explosions (Figure 1.129),the probability of ignition is higher than with inert-

ing. The plant is therefore designed to be able to withstand dust explosions without

becoming damaged, but such events are clearly undesirable. Therefore, continual mon-

itoring and control of a series of process variables is again recommended.In addition to

the sensors in Figure 1.128,Figure 1.129indicates sensors for detection of abnormalpres-

sure rise in the mill, the filter, and the coal dust silos and detectorsfor flames in the ducts

from the mill. On the other hand, measurement of oxygen concentrationis of less inter-

est in this case, because one has to accept that the oxygen content can be as high as in

air (21 ~01%).

In addition to stopping the mill, the fan, the rotary locks, and the conveyors, the pres-

sure and flame sensors can be used to activate various kinds of active isolation

in the ducting between the various process units that are not already isolated by the

rotary locks, a screw conveyor, or a passive explosion interrupter (see Section 1.4.4).

t may be argued that the instruments suggested in Figures 1.128 and 1.129is exces-

sive. This is a matter of discussion in each case. The main purpose has been to indicate

the possibilities that exist and from which one should select the appropriatemeasures to

suit a specific application.