Page 134 - Dust Explosions in the Process Industries

P. 134

Dust Explosions:An Overview 107

2 20

0

w

W

v,

g 10

a

3 w

z

3

E -

$ 1

1 5 10 30 100 250 1000

VESSEL VOLUME lm3l

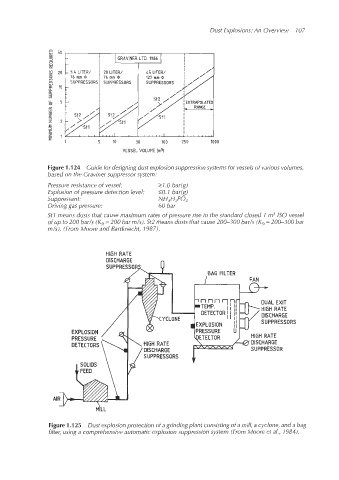

Figure 1.124 Guide for designing dust explosion suppression systems for vessels of various voiumes,

based on the Graviner suppressor system:

Pressure resistance of vessel: t1.0 bar(g)

Explos.ionof pressure detection level: SO. 1 bar(g)

Suppressant: NH,H, PO,

Driving gas pressure: 60 bar

St I means dusts that cause maximum rates of pressure rise in the standard closed 1 m3 IS0 vessel

of up to 200 bar/s (Ks, = 200 bar m/s). St2 means dusts that cause 200-300 bar/s (Ks,= 200-300 bar

m/s). (From Moore and Bartknecht, 1987).

HIGH RATE

DISCHARGE 0

SUPPRESSORS. BAG FILTER

M

SUPPRESSORS

PRESSURE '

DETECTORS HIGH RATE

I /DISCHARGE

SUPPRESSORS

-Y

ALL

Figure 1.I 25 Dust explosion protection ofa grinding plant consisting of a mill, a cyclone, and a bag

filter, using a comprehensive automatic explosion suppression system (From Moore et a/., 7 984).