Page 137 - Dust Explosions in the Process Industries

P. 137

1 IO Dust Explosions in the Process Industries

CHIMNEY

EXHAUST GAS FRO

ROTARY KILN

-RECYCLED GAS FROM DRYING

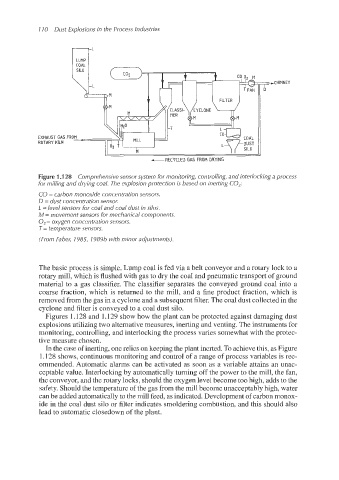

Figure 1 .I 28 Comprehensivesensor system for monitoring, controlling, and interlocking a process

for milling and drying coal. The explosion protection is based on inerting C02:

CO = carbon monoxide concentration sensors.

D = dust concentration sensor.

L = level sensors for coal and coal dust in silos.

M = movement sensors for mechanical components.

O2= oxygen concentration sensors.

T = temperature sensors.

(From Faber, 1985, 19896 with minor adjustments)

The basic process is simple. Lump coal is fed via a belt conveyor and a rotary lock to a

rotary mill, which is flushed with gas to dry the coal and pneumatic transport of ground

material to a gas classifier. The classifier separates the conveyed ground coal into a

coarse fraction, which is returned to the mill, and a fine product fraction, which is

removed from the gas in a cyclone and a subsequent filter. The coal dust collected in the

cyclone and filter is conveyed to a coal dust silo.

Figures 1.128 and 1.129 show how the plant can be protected against damaging dust

explosions utilizing two alternative measures, inerting and venting. The instruments for

monitoring, controlling, and interlocking the process varies somewhat with the protec-

tive measure chosen.

In the case of inerting, one relies on keeping the plant inerted. To achieve this, as Figure

1.128 shows, continuous monitoring and control of a range of process variables is rec-

ommended. Automatic alarms can be activated as soon as a variable attains an unac-

ceptable value. Interlocking by automatically turning off the power to the mill, the fan,

the conveyor, and the rotary locks, should the oxygen level become too high, adds to the

safety. Should the temperature of the gas from the mill become unacceptably high, water

can be added automatically to the mill feed, as indicated. Development of carbon nionox-

ide in the coal dust silo or filter indicates smoldering combustion, and this should also

lead to automatic closedown of the plant.