Page 131 - Dust Explosions in the Process Industries

P. 131

104 Dust Explosions in the Process Industries

1

1

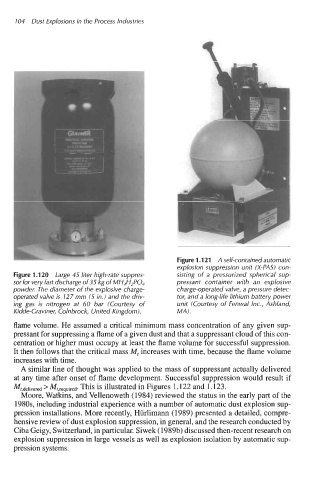

i Figure 1 .I 21 A self-contained automatic

explosion suppression unit (X-PAS) con-

Figure 1 .I 20 Large 45 liter high-rate suppres- sisting of a pressurized spherical sup-

sor for very fast discharge of 35 kg of MH,H,PO, pressant container with an explosive

powder. The diameter of the explosive charge- charge-operated valve, a pressure detec-

operated valve is 127 mm (5 in.) and the driv- tor, and a long-life lithium battery power

ing gas is nitrogen at 60 bar (Courtesy of unit (Courtesy of Fenwal Inc., Ashland,

Kidde-Craviner, Colnbrock, United Kingdom). MA).

flame volume. He assumed a critical minimum mass concentration of any given sup-

pressant for suppressing a flame of a given dust and that a suppressant cloud of this con-

centration or higher must occupy at least the flame volume for successful suppression.

It then follows that the critical mass Mt increases with time, because the flame volume

increases with time.

A similar line of thought was applied to the mass of suppressant actually delivered

at any time after onset of flame development. Successful suppression would result if

&ft,delivered > Mt,requlred. This is illustrated in Figures 1.122 and 1.123.

Moore, Watkins, and Vellenoweth (1984) reviewed the status in the early part of the

1980s, including industrial experience with a number of automatic dust explosion sup-

pression installations. More recently, Hiirlimann (1 989) presented a detailed, compre-

hensive review of dust explosion suppression, in general, and the research conducted by

Ciba Geigy, Switzerland, in particular. Siwek (1989b) discussed then-recent research on

explosion suppression in large vessels as well as explosion isolation by automatic sup-

pression systems.