Page 156 - Dust Explosions in the Process Industries

P. 156

Dust Explosions:An Overview 129

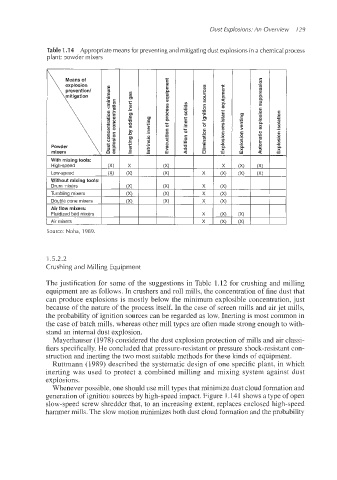

Table 1.I4 Appropriate means for preventing and mitigating dust explosions in a chemical process

plant: oowder mixers

Means of

explosion

prevention1

mitigation

\

Powder

mixers

With mixing tools:

High-speed

Low-speed

Without mixing tools:

Drum mixers

Tumbling mixers

Double cone mixers

Air flow mixers:

Fluidized bed mixers 0

Air mixers 0

Source: Noha, 1989.

1.5.2.2

Crushing and Milling Equipment

The justification for some of the suggestions in Table 1.12 for crushing and milling

equipment are as follows. In crushers and roll mills, the concentration of fine dust that

can produce explosions is mostly below the minimum explosible concentration, just

because of the nature of the process itself. In the case of screen mills and air jet mills,

the probability of ignition sources can be regarded as low. Inerting is most common in

the case of batch mills, whereas other mill types are often made strong enough to with-

stand an internal dust explosion.

ayerhauser (1978) considered the dust explosion protection of mills and air classi-

fiers specifically. He concluded that pressure-resistant or pressure shock-resistant con-

struction and inerting the two most suitable methods for these kinds of equipment.

Ruttmann (1989) described the systematic design of one specific plant, in which

inerting was used to protect a combined milling and mixing system against dust

explosions ~

enever possible, one should use mill types that minimize dust cloud formation and

generation of ignition sources by high-speed impact. Figure 1.141 shows a type of open

shredder that, to an increasing extent, replaces enclosed high-speed

slow motion minimizes both dust cloud formation and the prob