Page 92 - Dust Explosions in the Process Industries

P. 92

Dust Explosions: An Overview 65

Feed Chute

-A

of tkmpmetal

AIR INTAKE

TO MILL

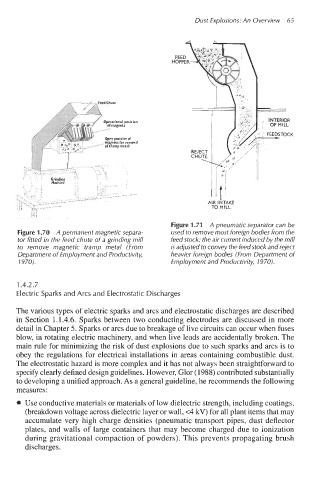

Figure 1.71 A pneumatic separator can be

Figure 1.70 A permanent magnetic separa- used to remove most foreign bodies from the

tor fitted in the feed chute of a grinding mill feed stock: the air current induced by the mill

to remove magnetic tramp metal (From is adjosted to convey the feed stock and reject

Department of Employment and Productivity, heavier foreign bodies (From Department of

1970). Employment and Productivity, 1970).

1.4.2.7

Electric Sparks and Arcs and Electrostatic Discharges

The various types of electric sparks and arcs and electrostatic discharges are described

in Section 1.1.4.6. Sparks between two conducting electrodes are discussed in more

detail in Chapter 5. Sparks or arcs due to breakage of live circuits can occur when fuses

blow, in rotating electric machinery, and when live leads are accidentally broken. The

main rule for minimizing the risk of dust explosions due to such sparks and arcs is to

obey the regulations for electrical installations in areas containing combustible dust.

The electrostatic hazard is more complex and it has not always been straightforward to

specify clearly defined design guidelines. However, Glor (1 988) contributed substantially

to developing a unified approach. As a general guideline, he recommends the following

measures:

Use conductive materials or materials of low dielectric strength, including coatings,

(breakdown voltage across dielectric layer or wall, <4 kV) for all plant items that may

accumulate very high charge densities (pneumatic transport pipes, dust deflector

plates, and walls of large containers that may become charged due to ionization

during gravitational compaction of powders). This prevents propagating brush

discharges.