Page 97 - Dust Explosions in the Process Industries

P. 97

70 Dust Explosions in the Process Industries

N2 INLET

MEASUREMENT

WITH FEEDBACK

WITH FEEDBACK

TO N2 SUPPLY

STORAGE

CONTAINER

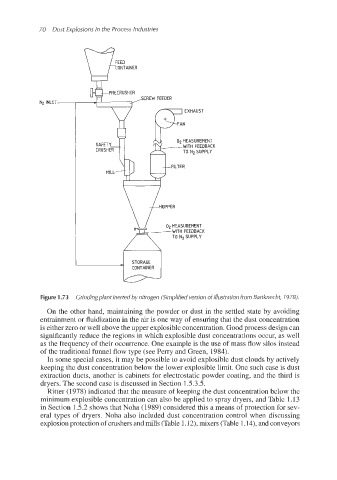

Figure1.73 Grindingplant inerted by nitrogen (Simplified version of illustration from Bartknecht, 1978).

On the other hand, maintaining the powder or dust in the settled state by avoiding

entrainment or fluidizationin the air is one way of ensuring that the dust concentration

is either zero or well above the upper explosible concentration.Good process design can

significantly reduce the regions in which explosible dust concentrations occur, as well

as the frequency of their occurrence. One example is the use of mass flow silos instead

of the traditional funnel flow type (see Perry and Green, 1984).

In some special cases, it may be possible to avoid explosible dust clouds by actively

keeping the dust concentration below the lower explosible limit. One such case is dust

extraction ducts, another is cabinets for electrostatic powder coating, and the third is

dryers. The second case is discussed in Section 1.5.3.5.

Ritter (1978) indicated that the measure of keeping the dust concentration below the

minimum explosible concentration can also be applied to spray dryers, and Table 1.13

in Section 1.5.2 shows that Noha (1989) considered this a means of protection for sev-

eral types of dryers. Noha also included dust concentration control when discussing

explosionprotection of crushers and mills (Table 1.12),mixers (Table 1.14),and conveyors