Page 99 - Dust Explosions in the Process Industries

P. 99

72 Dust Explosions in the Process Industries

01,

- - 04

I

I -

8 0.3

8 0.3

0

0

G 0.2

n

5 0.1

c

a

0

00 I

0 20 40 60 80 100

ACTUAL DUST CONCENTRATION Ig/dI

Figure 1.75 Optical density of clouds in air of wheat grain dust containing 10% moisture, length

of light path is 150 mm, optical density Dlois defined as

( incident light intensity

loglo light intensity after 150 mm

(From Eckhoff and Fuhre, 1975).

11111 Illill ARRANGEMENT FOR

FLUSHING WINDOWS

BY COMPRESSED AIR

LIGHT EMITTING PHOTO

DIODE [LED) DIODE

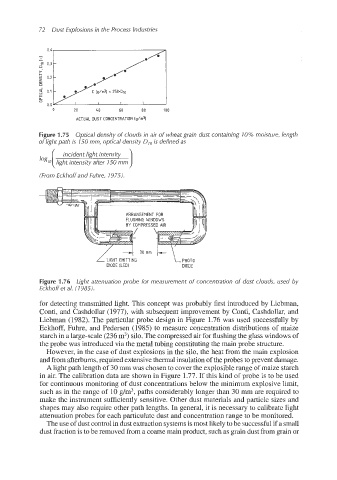

Figure 1.76 Light attenuation probe for measurement of concentration of dust clouds, used by

Eckhoff et al. (1985).

for detecting transmitted light. This concept was probably first introduced by Liebman,

Conti, and Cashdollar (1977), with subsequent improvement by Conti, Cashdollar, and

Liebman (1982). The particular probe design in Figure 1.76 was used successfully by

Eckhoff, Fuhre, and Pedersen (1985) to measure concentration distributions of maize

starch in a large-scale (236 m3)silo. The compressed air for flushing the glass windows of

the probe was introduced via the metal tubing constituting the main probe structure.

However, in the case of dust explosions in the silo, the heat from the main explosion

and from afterburns,required extensive thermal insulation of the probes to prevent damage.

A light path length of 30 mm was chosen to cover the explosiblerange of maize starch

in air. The calibration data are shown in Figure 1.77. If this kind of probe is to be used

for continuous monitoring of dust concentrations below the minimum explosive limit,

such as in the range of 10 g/m3,paths considerably longer than 30 mm are required to

make the instrument sufficiently sensitive. Other dust materials and particle sizes and

shapes may also require other path lengths. In general, it is necessary to calibrate light

attenuation probes for each particulate dust and concentration range to be monitored.

The use of dust control in dust extractionsystemsis most likely to be successfulif a small

dust fraction is to be removed from a coarse main product, such as grain dust from grain or