Page 103 - Dust Explosions in the Process Industries

P. 103

76 Dust Explosions in the Process Industries

Wheeler conducted similar experiments with rotary locks. A hopper section mounted

on top of the rotary lock was connected to the 3.5 m3 explosion vessel. Even when the

hopper was empty of rice meal, there was no flame transmission through the rotary lock.

When the hopper contained rice meal and the rotary lock was rotating, there was not even

transmission of pressure, and the rice meal remained intact in the hopper.

In more recent years, Schuber (1989) and Siwek (1989a) conducted extensive studies

of the conditions under which a rotary lock is capable of preventing transmission of dust

explosions. Schuber provided a nomograph by which critical design parameters for

explosion-transmission-resistantrotary locks can be determined. The minimum igni-

tion energy and minimum ignitiontemperature of the dust must be known. However, the

nomograph does not apply to metal dust explosions. Explosions of fine aluminum are

difficult to stop by rotary locks. Schuber’swork is described in detail in Chapter 4 in the

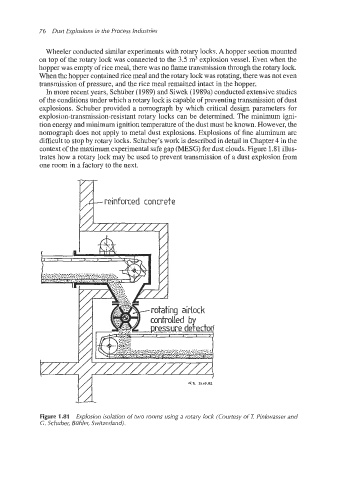

context of the maximum experimentalsafe gap (MESG) for dust clouds. Figure 1.81illus-

trates how a rotary lock may be used to prevent transmission of a dust explosion from

one room in a factory to the next.

reinforced concrete

G.S. 2c.to.o~

Figure 1.81 Explosion isolation of two rooms using a rotary lock [Courtesy of T: Pinkwasser and

C. Schuber, Buhler, Switzerland).