Page 105 - Dust Explosions in the Process Industries

P. 105

78 Dust Explosions in the Process Industries

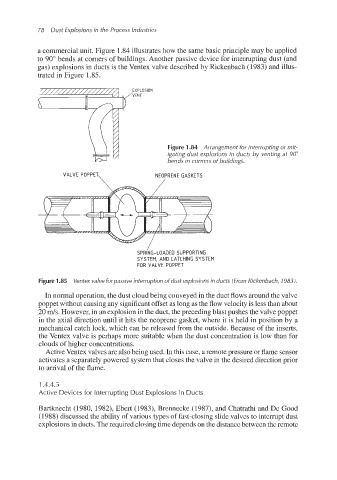

a commercial unit. Figure 1.84 illustrates how the same basic principle may be applied

to 90" bends at comers of buildings. Another passive device for interrupting dust (and

gas) explosions in ducts is the Ventex valve described by Rickenbach (1983) and illus-

trated in Figure 1.85.

EXPLOSION

VENT

Figure 1.84 Arrangement for interrupting or mit-

igating dust explosions in ducts by venting at 90"

bends in corners of buildings.

VALVE POPPE

/

SPRING-LOADED SUPPORTING

SYSTEM, AND CATCHING SYSTEM

FOR VALVE POPPET

Figure 1.85 Ventex valvefor passive interruption of dust explosions inducts (From Rickenbach, 7983).

In normal operation, the dust cloud being conveyed in the duct flows around the valve

poppet without causing any significantoffset as long as the flow velocity is less than about

20 ds. However, in an explosion in the duct, the preceding blast pushes the valve poppet

in the axial direction until it hits the neoprene gasket, where it is held in position by a

mechanical catch lock, which can be released from the outside. Because of the inserts,

the Ventex valve is perhaps more suitable when the dust concentration is low than for

clouds of higher concentrations.

Active Ventex valves are also being used. In this case, a remote pressure or flame sensor

activates a separatelypowered system that closes the valve in the desired directionprior

to arrival of the flame.

1.4.4.5

Active Devices for Interrupting Dust Explosions in Ducts

Bartknecht (1980, 1982), Ebert (1983), Brennecke (1987), and Chatrathi and De Good

(1988) discussed the ability of various types of fast-closing slide valves to interrupt dust

explosionsin ducts.The required closing time depends on the distancebetween the remote