Page 106 - Dust Explosions in the Process Industries

P. 106

Dust Explosions: An Overview 79

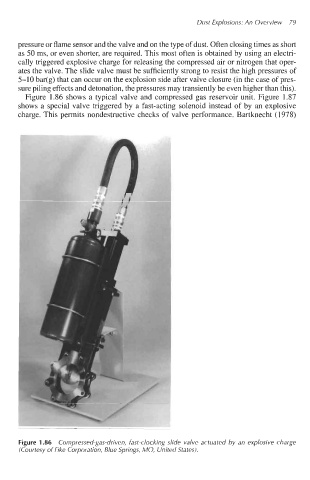

pressure or flame sensor and the valve and on the type of dust. Often closing times as short

as 50 ms, or even shorter, are required. This most often is obtained by using an electri-

cally triggered explosive charge for releasing the compressed air or nitrogen that oper-

ates the valve. The slide valve must be sufficiently strong to resist the high pressures of

5-10 bar(g) that can occur on the explosion side after valve closure (in the case of pres-

sure piling effects and detonation, the pressures may transiently be even higher than this).

Figure 1.86 shows a typical valve and compressed gas reservoir unit. Figure 1.87

shows a special valve triggered by a fast-acting solenoid instead of by an explosive

charge. This permits nondestructive checks of valve performance. Bartknecht (1978)

Figure 1.86 Compressed-gas-driven, fast-clocking slide valve actuated by an explosive charge

(Courtesy of Fike Corporation, Blue Springs, MO, United States).