Page 110 - Dust Explosions in the Process Industries

P. 110

Dust Explosions: An Overview 83

the one that gives a strain of 2%. However, in the latter case, repair of deformed process

equipment must be foreseen, should an explosion occur.

If dust explosions in the plant of concern were fairly frequent events, one might con-

sider the use of the pressure vessel design approach, because the deformations that often

result with the pressure-shock-resistant design would be avoided. This is a matter of ana-

lyzing cost versus benefit. From the point of view of safety, the main concern is to pro-

tect personnel, that is, avoid the rupture of process equipment.

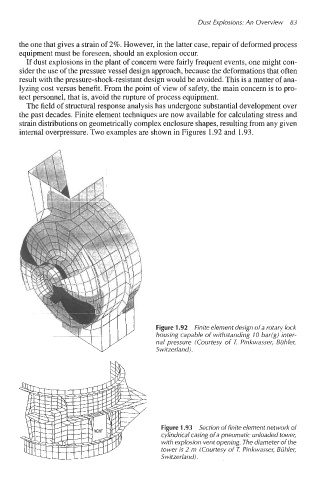

The field of structural response analysis has undergone substantial development over

the past decades. Finite element techniques are now available for calculating stress and

strain distributions on geometrically complex enclosure shapes, resulting from any given

internal overpressure. Two examples are shown in Figures 1.92 and 1.93.

Figure 1.92 Finite element design of a rotary lock

housing capable of withstanding 7 0 bar(g) inter-

nal pressure (Courtesy of T. Pinkwasser, Buhler,

Switzerland).

Figure 1.93 Section of finite element network of

cylindrical casing of a pneumatic unloaded tower,

with explosion vent opening. The diameter of the

tower is 2 m (Courtesy of T. Pinkwasser, Buhler,

Switzerland).