Page 113 - Dust Explosions in the Process Industries

P. 113

86 Dust Explosions in the Process Industries

0 Enclosure volume.

Enclosure strength (Pred).

Strength of vent cover (Pstat).

Burning rate of dust cloud.

For some time it was thought by many that the burning rate of the dust cloud was a

specific property of a given dust, which could be determined once and for all in a stan-

dard 1 m3closed vessel test (Kstvalue, see Chapter 4).

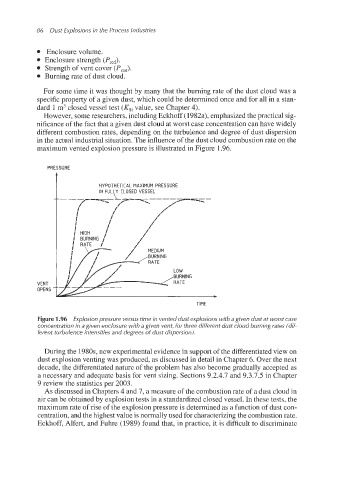

However, some researchers, including Eckhoff (1982a), emphasizedthe practical sig-

nificance of the fact that a given dust cloud at worst case concentrationcan have widely

different combustion rates, depending on the turbulence and degree of dust dispersion

in the actual industrial situation. The influence of the dust cloud combustion rate on the

maximum vented explosion pressure is illustrated in Figure 1.96.

PRESSURE

HYPOTHETICAL MAXIMUM PRESSURE

IN FULLY CLOSED VESSEL

.-

LOW

BURNING

RATE

w

TIME

Figure 1.96 Explosion pressure versus time in vented dust explosions with a given dust at worst case

concentration in a given enclosure with a given vent, for three different dust cloud burning rates (dif-

ferent turbulence intensities and degrees of dust dispersion).

During the 1980s,new experimentalevidence in support of the differentiatedview on

dust explosion venting was produced, as discussed in detail in Chapter 6. Over the next

decade, the differentiated nature of the problem has also become gradually accepted as

a necessary and adequate basis for vent sizing. Sections 9.2.4.7 and 9.3.7.5 in Chapter

9 review the statistics per 2003.

As discussed in Chapters 4 and 7, a measure of the combustion rate of a dust cloud in

air can be obtained by explosion tests in a standardizedclosed vessel. In these tests, the

maximum rate of rise of the explosion pressure is determined as a function of dust con-

centration, and the highest value is normally used for characterizingthe combustionrate.

Eckhoff, Alfert, and Fuhre (1989) found that, in practice, it is difficult to discriminate