Page 117 - Dust Explosions in the Process Industries

P. 117

*-

90 Dust Explosions in the Process Industries

bPROXIMITY SWITCH

FLAME ARRESTER AND

VACUUM SUPPORT

FOR ALUMINIUM FOIL

(0.5 mm METAL GAUZE)

ALUMINIUM FOIL (0.04mml-

1 FLAME ARRESTER AND

MECHANICAL PROTECTION

FOR ALUMINUM FOIL

(0.5 mm METAL GAUZE1

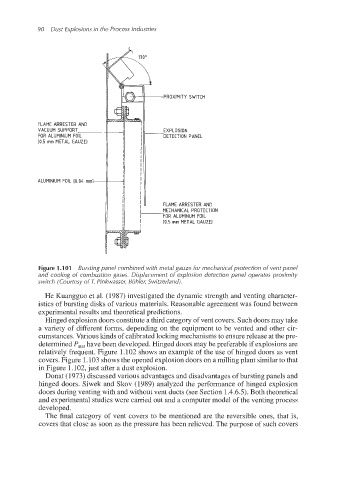

Figure 1 .I 01 Bursting panel combined with metal gauze for mechanical protection of vent panel

and cooling of combustion gases. Displacement of explosion detection panel operates proximity

switch (Courtesy of T. Pinkwasser,Buhler, Switzerland).

He Kuangguo et al. (1987) investigated the dynamic strength and venting character-

istics of bursting disks of various materials. Reasonable agreement was found between

experimental results and theoretical predictions.

Hinged explosion doors constitute a third category of vent covers. Such doors may take

a variety of different forms, depending on the equipment to be vented and other cir-

cumstances.Various kinds of calibratedlocking mechanisms to ensure release at the pre-

determinedp,,,, have been developed. Hinged doors may be preferable if explosions are

relatively frequent. Figure 1.102 shows an example of the use of hinged doors as vent

covers. Figure 1.103shows the opened explosion doors on a milling plant similarto that

in Figure 1.102,just after a dust explosion.

Donat (1973) discussed various advantages and disadvantages of bursting panels and

hinged doors. Siwek and Skov (1989) analyzed the performance of hinged explosion

doors during venting with and without vent ducts (see Section 1.4.6.5).Both theoretical

and experimental studies were carried out and a computer model of the venting process

developed.

The final category of vent covers to be mentioned are the reversible ones, that is,

covers that close as soon as the pressure has been relieved. The purpose of such covers