Page 121 - Dust Explosions in the Process Industries

P. 121

94 Dust Explosions in the Process Industries

WEATHER

PROTECTION

HOOD

Y VENT PANEL

Figure 1.I 06 The use of a vent duct for guiding dis-

charged unburned dust cloud and flames to a safe

place.

..

in the vented vessel. Furthermore, the pressure increases with increasing duct lengtn,

increasing number of sharp bends, and decreasing duct diameter. These trends are con-

firmed by experiments.

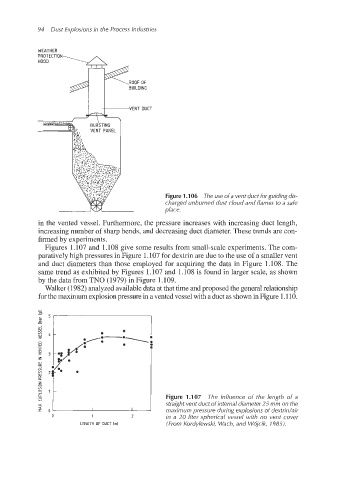

Figures 1.107 and 1.108 give some results from small-scale experiments. The com-

paratively high pressures in Figure 1.107 for dextrin are due to the use of a smaller vent

and duct diameters than those employed for acquiring the data in Figure 1.108. The

same trend as exhibited by Figures 1.107 and 1.108 is found in larger scale, as shown

by the data from TNO (1979) in Figure 1.109.

Walker (1982) analyzed availabledata at that time and proposed the generalrelationship

forthe maximum explosionpressure in a vented vessel with a duct as shown in Figure 1.110.

W

VI

VI

w 4

7

n

Y c

E

> 3

z

w

CL

3

v)

M 2

CLa

Figure 1.107 The influence of the length of a

x straight vent duct ofinternal diameter 25 mm on the

; a I maximum pressure during explosions of dextridair

EO

0 1 2 in a 20 liter spherical vessel with no vent cover

LENGTH OF DUCT Iml (From Kordylewski, Wach, and Wijcik, 7 985).