Page 119 - Dust Explosions in the Process Industries

P. 119

92 Dust Explosions in the Process Industries

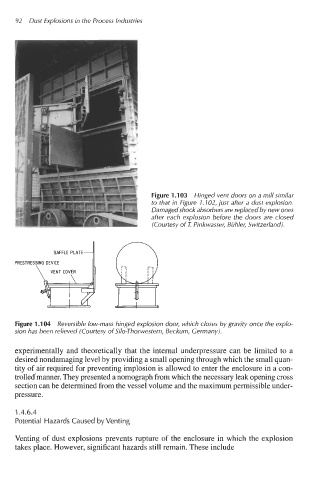

Figure 1 .I 03 Hinged vent doors on a mill similar

to that in Figure 1.102, just after a dust explosion.

Damaged shock absorbers are replaced by new ones

after each explosion before the doors are closed

(Courtesy of T. Pinkwasser, Biihler, Switzerland).

BAFFLE PLATE

Figure 1 .I 04 Reversible low-mass hinged explosion door, which closes by gravity once the explo-

sion has been relieved (Courtesy of Silo-Thorwestern, Beckurn, Germany).

experimentally and theoretically that the internal underpressure can be limited to a

desired nondamaging level by providing a small opening through which the small quan-

tity of air required for preventing implosion is allowed to enter the enclosure in a con-

trolled'manner. They presented a nomograph from which the necessary leak opening cross

section can be determined from the vessel volume and the maximum permissible under-

pressure.

1 A.6.4

Potential Hazards Caused by Venting

Venting of dust explosions prevents rupture of the enclosure in which the explosion

takes place. However, significant hazards still remain. These include