Page 115 - Dust Explosions in the Process Industries

P. 115

88 Dust Explosions in the Process Industries

vent covers used in the Swedish process industries for venting of process equipment as

well as workrooms. Their conclusion was that a number of the vent covers inspected

would not have performed adequately in the event of an explosion. They emphasized the

need for ensuring that the static opening pressure of the vent cover is sufficiently low

and remains so over time and that the mass of the cover is sufficiently small to permit

rapid acceleration once released. Beigler (1983) subsequentlydeveloped an approximate

theory for the acceleration of a vent cover away from the vent opening.

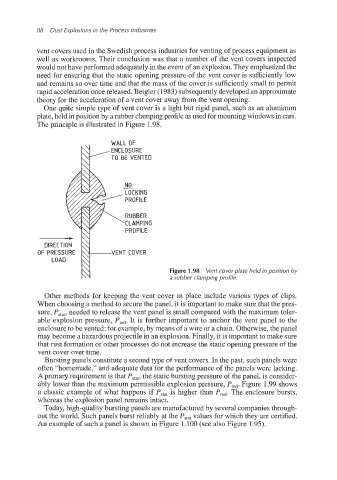

One quite simple type of vent cover is a light but rigid panel, such as an aluminum

plate, held in position by a rubber clampingprofile as used for mounting windows in cars.

The principle is illustrated in Figure 1.98.

TO BE VENTED

Figure 1.98 Vent cover plate held in position by

a rubber clamping profile.

Other methods for keeping the vent cover in place include various types of clips.

When choosing a method to secure the panel, it is important to make sure that the pres-

sure, Pstat,needed to release the vent panel is small compared with the maximum toler-

able explosion pressure, Pred. It is further important to anchor the vent panel to the

enclosureto be vented; for example, by means of a wire or a chain. Otherwise,the panel

may become a hazardous projectile in an explosion.Finally, it is important to make sure

that rust formation or other processes do not increase the static opening pressure of the

vent cover over time.

Bursting panels constitute a second type of vent covers. In the past, such panels were

often “homemade,”and adequate data for the performance of the panels were lacking.

A primary requirement is that PStat,the static bursting pressure of the panel, is consider-

ably lower than the maximum permissible explosion pressure, Pred. Figure 1.99 shows

a classic example of what happens if P,,,, is higher than Pred. The enclosure bursts,

whereas the explosion panel remains intact.

Today, high-quality bursting panels are manufactured by several companies through-

out the world. Such panels burst reliably at the P,,, values for which they are certified.

An example of such a panel is shown in Figure 1.100 (see also Figure 1.95).