Page 179 - Dynamics and Control of Nuclear Reactors

P. 179

176 CHAPTER 13 Boiling water reactors

CONTAINMENT

SPRAY

SHIELD BUILDING

125 TON CRANE W/15 TON AUX HOOK

CONTAINMENT

UPPER POOL

DRYWELL HEAD

FUEL TRANSFER

POOL

REACTOR VESSEL

REACTOR SHIELD

DRYWELL BOUNDRY

WEIR WALL DRYWELL

FUEL TRANSFER

S/R VALVE LINE

TUBE

SUPRESSION

POOL

HORIZONTAL

VENT

(C)

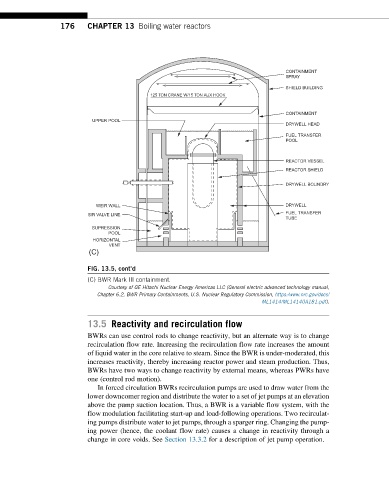

FIG. 13.5, cont’d

(C) BWR Mark III containment.

Courtesy of GE Hitachi Nuclear Energy Americas LLC (General electric advanced technology manual,

Chapter 6.2, BWR Primary Containments, U.S. Nuclear Regulatory Commission, https://www.nrc.gov/docs/

ML1414/ML14140A181.pdf).

13.5 Reactivity and recirculation flow

BWRs can use control rods to change reactivity, but an alternate way is to change

recirculation flow rate. Increasing the recirculation flow rate increases the amount

of liquid water in the core relative to steam. Since the BWR is under-moderated, this

increases reactivity, thereby increasing reactor power and steam production. Thus,

BWRs have two ways to change reactivity by external means, whereas PWRs have

one (control rod motion).

In forced circulation BWRs recirculation pumps are used to draw water from the

lower downcomer region and distribute the water to a set of jet pumps at an elevation

above the pump suction location. Thus, a BWR is a variable flow system, with the

flow modulation facilitating start-up and load-following operations. Two recirculat-

ing pumps distribute water to jet pumps, through a sparger ring. Changing the pump-

ing power (hence, the coolant flow rate) causes a change in reactivity through a

change in core voids. See Section 13.3.2 for a description of jet pump operation.