Page 12 - Electric Drives and Electromechanical Systems

P. 12

4 Electric Drives and Electromechanical Systems

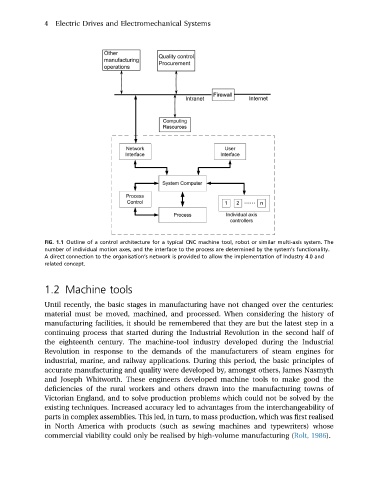

FIG. 1.1 Outline of a control architecture for a typical CNC machine tool, robot or similar multi-axis system. The

number of individual motion axes, and the interface to the process are determined by the system’s functionality.

A direct connection to the organisation’s network is provided to allow the implementation of Industry 4.0 and

related concept.

1.2 Machine tools

Until recently, the basic stages in manufacturing have not changed over the centuries:

material must be moved, machined, and processed. When considering the history of

manufacturing facilities, it should be remembered that they are but the latest step in a

continuing process that started during the Industrial Revolution in the second half of

the eighteenth century. The machine-tool industry developed during the Industrial

Revolution in response to the demands of the manufacturers of steam engines for

industrial, marine, and railway applications. During this period, the basic principles of

accurate manufacturing and quality were developed by, amongst others, James Nasmyth

and Joseph Whitworth. These engineers developed machine tools to make good the

deficiencies of the rural workers and others drawn into the manufacturing towns of

Victorian England, and to solve production problems which could not be solved by the

existing techniques. Increased accuracy led to advantages from the interchangeability of

parts in complex assemblies. This led, in turn, to mass production, which was first realised

in North America with products (such as sewing machines and typewriters) whose

commercial viability could only be realised by high-volume manufacturing (Rolt, 1986).