Page 203 - Electromechanical Devices and Components Illustrated Sourcebook

P. 203

Chapter 9 Connectors 165

used to mount the strip. Spacers are fitted to the studs and

thumb nuts are used to secure the protective plate. The plate

can also serve to identify the function of the device by print-

ing a label on the top as shown.

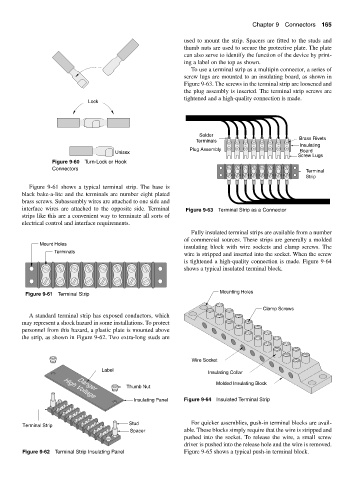

To use a terminal strip as a multipin connector, a series of

screw lugs are mounted to an insulating board, as shown in

Figure 9-63. The screws in the terminal strip are loosened and

the plug assembly is inserted. The terminal strip screws are

tightened and a high-quality connection is made.

Lock

Solder

Brass Rivets

Terminals

Insulating

Plug Assembly

Unisex Board

Screw Lugs

Figure 9-60 Turn-Lock or Hook

Connectors

Terminal

Strip

Figure 9-61 shows a typical terminal strip. The base is

black bake-a-lite and the terminals are number eight plated

brass screws. Subassembly wires are attached to one side and

interface wires are attached to the opposite side. Terminal Figure 9-63 Terminal Strip as a Connector

strips like this are a convenient way to terminate all sorts of

electrical control and interface requirements.

Fully insulated terminal strips are available from a number

of commercial sources. These strips are generally a molded

Mount Holes

insulating block with wire sockets and clamp screws. The

Terminals

wire is stripped and inserted into the socket. When the screw

is tightened a high-quality connection is made. Figure 9-64

shows a typical insulated terminal block.

Mounting Holes

Figure 9-61 Terminal Strip

Clamp Screws

A standard terminal strip has exposed conductors, which

may represent a shock hazard in some installations. To protect

personnel from this hazard, a plastic plate is mounted above

the strip, as shown in Figure 9-62. Two extra-long studs are

Wire Socket

Label

Insulating Collar

Molded Insulating Block

Thumb Nut

Danger

High Voltage

Insulating Panel Figure 9-64 Insulated Terminal Strip

Stud For quicker assemblies, push-in terminal blocks are avail-

Terminal Strip

Spacer able. These blocks simply require that the wire is stripped and

pushed into the socket. To release the wire, a small screw

driver is pushed into the release hole and the wire is removed.

Figure 9-62 Terminal Strip Insulating Panel Figure 9-65 shows a typical push-in terminal block.