Page 204 - Electromechanical Devices and Components Illustrated Sourcebook

P. 204

166 Electromechanical Devices & Components Illustrated Sourcebook

Cable

Release Hole

Lugs

Mounting Brass Screw and Nut

Holes Insulating Board

Wire Socket

Unique Spacing

Mounting Hole

on Each Terminal

Molded Insulating Block

Copper Strip

Solder Terminals

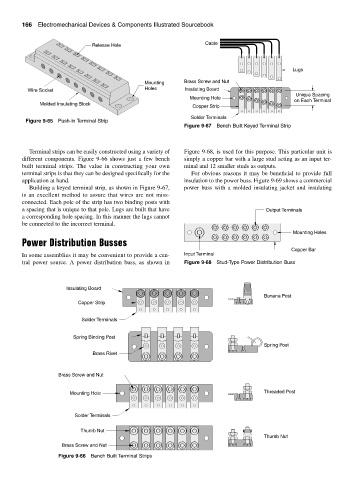

Figure 9-65 Push-in Terminal Strip

Figure 9-67 Bench Built Keyed Terminal Strip

Terminal strips can be easily constructed using a variety of Figure 9-68, is used for this purpose. This particular unit is

different components. Figure 9-66 shows just a few bench simply a copper bar with a large stud acting as an input ter-

built terminal strips. The value in constructing your own minal and 12 smaller studs as outputs.

terminal strips is that they can be designed specifically for the For obvious reasons it may be beneficial to provide full

application at hand. insulation to the power buss. Figure 9-69 shows a commercial

Building a keyed terminal strip, as shown in Figure 9-67, power buss with a molded insulating jacket and insulating

is an excellent method to assure that wires are not miss-

connected. Each pole of the strip has two binding posts with

a spacing that is unique to that pole. Lugs are built that have Output Terminals

a corresponding hole spacing. In this manner the lugs cannot

be connected to the incorrect terminal.

Mounting Holes

Power Distribution Busses

Copper Bar

In some assemblies it may be convenient to provide a cen- Input Terminal

tral power source. A power distribution buss, as shown in Figure 9-68 Stud-Type Power Distribution Buss

Insulating Board

Banana Post

Copper Strip

Solder Terminals

Spring Binding Post

Spring Post

Brass Rivet

Brass Screw and Nut

Mounting Hole Threaded Post

Solder Terminals

Thumb Nut

Thumb Nut

Brass Screw and Nut

Figure 9-66 Bench Built Terminal Strips