Page 47 - Elements of Chemical Reaction Engineering 3rd Edition

P. 47

Sec. 1 .!5 Industrial Reactors 19

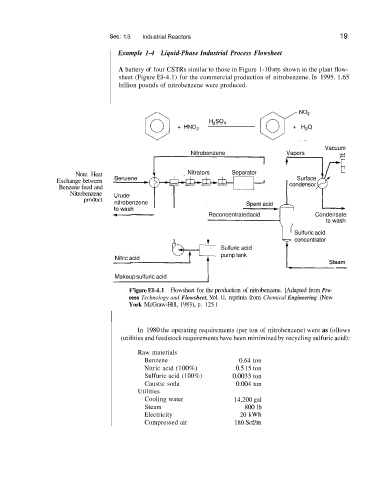

Example 1-4 Liquid-Phase Industrial Process Flowsheet

A battery of four CSTRs similar to those in Figure 1-10 ace shown in the plant flow-

sheet (Figure El-4.1) for the commercial production of nitrobenzene. In 1995. 1.65

billion pounds of nitrobenzene were produced.

Vacuum

Nitrobenzene Vapors

Note. Heat Nitrators Separator

Exchange between Benzene Surface

Benzene feed and

Nitrobenzene Crude

product nitrobenzene

c- Reconcentrated acid Condensate

to wash

Sulfuric acid

concentrator

Sulfuric acid

- pump tank Steam

Nitric acid

-

- I

Makeup sulfuric acid

F’igure El-4.1 Flowsheet for the production of nitrobenzene. [Adapted from Pro-

cess Technology and Flowsheet, Vol. 11, reprints from Chemical Engineering (New

York McGraw-Hill, 1983), p. 125.1

In 1980 the operating requirements (per ton of nitrobenzene) were as follows

(utilities and feedstock requirements have been minimized by recycling sulfuric acid):

Raw materials

Benzene 0.64 ton

Nitric acid (100%) 0.5 15 ton

Sulfuric acid (100%) 0.0033 ton

Caustic soda 0.004 ton

Utilities

Cooling water 14,200 gal

Steam 800 lb

Electricity 20 kWh

Compressed air 180 Scf/m