Page 42 - Academic Press Encyclopedia of Physical Science and Technology 3rd BioTechnology

P. 42

P1: GLM Revised Pages

Encyclopedia of Physical Science and Technology EN002G-62 May 19, 2001 19:27

182 Biomaterials, Synthetic Synthesis, Fabrication, and Applications

TABLE IV Metals Used in Medical Devices

Metal Medical device applications

Cobalt–chromium alloys Dental applicances, fracture plates, heart

valves, joint components, nails, screws

Titanium alloys Conductive leads, joint components,

pacemaker cases, nails, screws

Stainless steel Fracture plates

and benzyl hyaluronic acid ester (HYAFF-11) are used to FIGURE 5 Schematic diagram of grain boundaries between crys-

replace short nerve segments and in wound healing. The tallites. The boundaries may occupy only one row of atoms or

more.

materials can be used as threads, films, fabrics and sponges

and additional aplications are expected in plastic surgery

and orthopedics.

incorporate a wide range of different atoms either within

the crystal lattice, at interstitial sites within the crystal

C. Metals

lattice (spaces/sites where atoms or ions are not normally

Metals have a large range of applications as devices for located), or at grain boundaries and thus a multitude of

fracture fixation, joint replacement, surgical instruments, metal-containing materials can be made. The deformation

external splints, braces and traction apparatus, as well as characteristics of a metal are determined by the grain size

dental amalgams (Table IV). The high modulus and yield of the crystals as imperfections are concentrated at the

point coupled with the ductility of metals makes them grain boundaries. Mixing of metal atoms of different sizes

suitable for bearing heavy loads without large deforma- as in the production of an alloy can serve to modify the

tions and permanent size changes. Metals are generally properties of the metallic phase. Metallic elements used in

inert and if the composition is chosen carefully do not the formation of implants include: aluminium (Al), cobalt

degrade in a saline environment. Metals are crystalline (Co), chromium (Cr), copper (Cu), gold (Au), iridium

materials with a specific arrangement of metal atoms (Ir), iron (Fe), manganese (Mn), molybdenum (Mo),

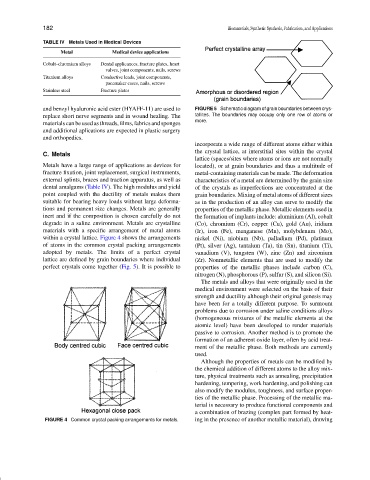

within a crystal lattice. Figure 4 shows the arrangements nickel (Ni), niobium (Nb), palladium (Pd), platinum

of atoms in the common crystal packing arrangements (Pt), silver (Ag), tantalum (Ta), tin (Sn), titanium (Ti),

adopted by metals. The limits of a perfect crystal vanadium (V), tungsten (W), zinc (Zn) and zirconium

lattice are defined by grain boundaries where individual (Zr). Nonmetallic elements that are used to modify the

perfect crystals come together (Fig. 5). It is possible to properties of the metallic phases include carbon (C),

nitrogen (N), phosphorous (P), sulfur (S), and silicon (Si).

The metals and alloys that were originally used in the

medical environment were selected on the basis of their

strength and ductility although their original genesis may

have been for a totally different purpose. To surmount

problems due to corrosion under saline conditions alloys

(homogeneous mixtures of the metallic elements at the

atomic level) have been developed to render materials

passive to corrosion. Another method is to promote the

formation of an adherent oxide layer, often by acid treat-

ment of the metallic phase. Both methods are currently

used.

Although the properties of metals can be modified by

the chemical addition of different atoms to the alloy mix-

ture, physical treatments such as annealing, precipitation

hardening, tempering, work hardening, and polishing can

also modify the modulus, toughness, and surface proper-

ties of the metallic phase. Processing of the metallic ma-

terial is necessary to produce functional components and

a combination of brazing (complex part formed by heat-

FIGURE 4 Common crystal packing arrangements for metals. ing in the presence of another metallic material), drawing