Page 47 - Academic Press Encyclopedia of Physical Science and Technology 3rd BioTechnology

P. 47

P1: GLM Revised Pages

Encyclopedia of Physical Science and Technology EN002G-62 May 19, 2001 19:27

Biomaterials, Synthetic Synthesis, Fabrication, and Applications 187

extremely high viscosity of silicate melts with high 600–700 C. The two methods of solvent removal give a

◦

silica content. much better control over sample purity. Advantages of

4. High temperature processing leads to increased the technology are the ability to make materials with

processing costs. a much wider range of composition and/or microstruc-

5. The relative expense of sol-gel materials relative to ture through manipulation of the processing parameters.

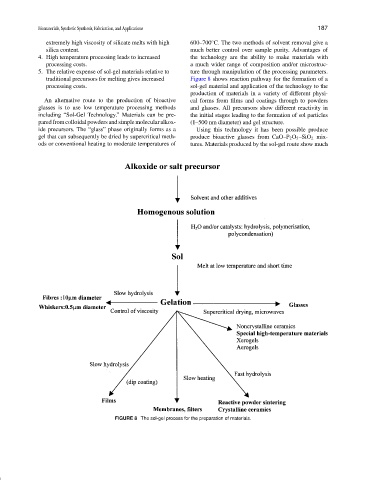

traditional precursors for melting gives increased Figure 8 shows reaction pathway for the formation of a

processing costs. sol-gel material and application of the technology to the

production of materials in a variety of different physi-

An alternative route to the production of bioactive cal forms from films and coatings through to powders

glasses is to use low temperature processing methods and glasses. All precursors show different reactivity in

including “Sol-Gel Technology.” Materials can be pre- the initial stages leading to the formation of sol particles

pared from colloidal powders and simple molecular alkox- (1–500 nm diameter) and gel structure.

ide precursors. The “glass” phase originally forms as a Using this technology it has been possible produce

gel that can subsequently be dried by supercritical meth- produce bioactive glasses from CaO–P 2 O 5 –SiO 2 mix-

ods or conventional heating to moderate temperatures of tures. Materials produced by the sol-gel route show much

FIGURE 8 The sol-gel process for the preparation of materials.