Page 463 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 463

P1: GNH/GUR P2: GPJ Final Pages

Encyclopedia of Physical Science and Technology EN014A-654 July 28, 2001 16:35

Reactors in Process Engineering 25

a. Gas–liquid

b. Gas–solid

c. Liquid–solid

d. Gas–liquid–solid

Multiphase reactor configurations are strongly influenced

by mass transfer operations. Any of the reactor types pre-

sented above can be operated as multiphase reactors.

C. Reaction Types

Classification of reactors can also be made by reaction

type.

1. Catalytic. Reactions that require the presence of a

catalyst to obtain the rate conditions necessary for

that particular reactor design

2. Noncatalytic. Reactions that do not include either a

homogeneous or heterogeneous catalyst

3. Autocatalytic. Reaction scheme whereby one of the

products increases the overall rate of reaction

4. Biological. Reactions that involve living cells

(enzymes, bacteria, or yeast), parts of cells, or

products from cells required for the reaction

scheme

5. Polymerization. Reactions that involve formation of

molecular chains, whether on a solid support or in

solution.

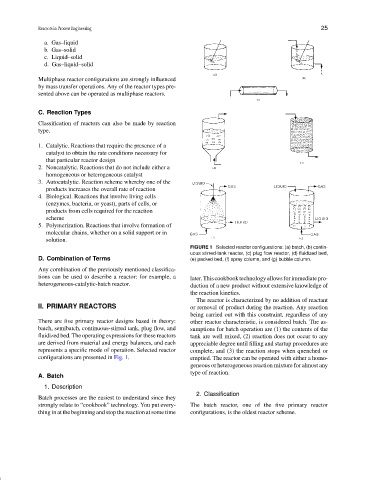

FIGURE 1 Selected reactor configurations: (a) batch, (b) contin-

uous stirred-tank reactor, (c) plug flow reactor, (d) fluidized bed,

D. Combination of Terms (e) packed bed, (f) spray column, and (g) bubble column.

Any combination of the previously mentioned classifica-

tions can be used to describe a reactor: for example, a later.Thiscookbooktechnologyallowsforimmediatepro-

heterogeneous-catalytic-batch reactor. duction of a new product without extensive knowledge of

the reaction kinetics.

The reactor is characterized by no addition of reactant

II. PRIMARY REACTORS or removal of product during the reaction. Any reaction

being carried out with this constraint, regardless of any

There are five primary reactor designs based in theory: other reactor characteristic, is considered batch. The as-

batch, semibatch, continuous-stirred tank, plug flow, and sumptions for batch operation are (1) the contents of the

fluidized bed. The operating expressions for these reactors tank are well mixed, (2) reaction does not occur to any

are derived from material and energy balances, and each appreciable degree until filling and startup procedures are

represents a specific mode of operation. Selected reactor complete, and (3) the reaction stops when quenched or

configurations are presented in Fig. 1. emptied. The reactor can be operated with either a homo-

geneous or heterogeneous reaction mixture for almost any

type of reaction.

A. Batch

1. Description

2. Classification

Batch processes are the easiest to understand since they

strongly relate to “cookbook” technology. You put every- The batch reactor, one of the five primary reactor

thing in at the beginning and stop the reaction at some time configurations, is the oldest reactor scheme.