Page 207 - Academic Press Encyclopedia of Physical Science and Technology 3rd Analytical Chemistry

P. 207

P1: ZCK/MBQ P2: GQT Final Pages

Encyclopedia of Physical Science and Technology EN008B-382 June 30, 2001 18:58

674 Liquid Chromatography

a particle-supported stationary phase is the technique

termed liquid chromatography (LC). There are two major

types of LC, classical and high-performance liquid chro-

matography (HPLC). Classical LC uses large columns

approximately 2 × 50 cm, packed with large porous par-

ticles 50–250 µm in diameter. Sample volumes in the

milliliter range are often required. The mobile phase is

generally gravity-fed at slow flow rates because the deep

pores of the packing limit mass transfer and separation

times can be on the order of hours. Fraction collection

of the components for later spectroscopic identification is

common. Although inefficient and not sensitive, classical

LC requires no special equipment and is often adequate

for some organic synthesis and biochemical research. The

evolution of HPLC occurred in the late 1960s as the tech-

nology became available to manufacture pellicular (see

Glossaryfordefinition)and10-µmsizeporoussilicaparti-

cles. These tiny particles when packed in smaller columns

of 0.4 × 25 cm require pumping of the mobile phase to

overcome the pressure drop of 1000 to 3000 psi. Because FIGURE 1 Block diagram of a high-performance liquid chromato-

of the shallower pores in these packing, mass transfer of graph; —–, Mobile phase flow; ---, computer control of device;

—·—· data acquisition and readout.

the analyte from the bulk of the mobile phase to the sur-

face of the stationary phase is faster, permitting separation

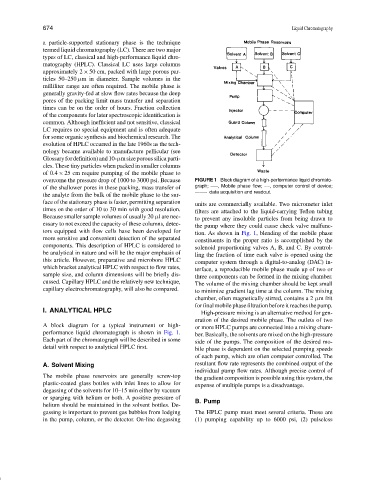

units are commercially available. Two micrometer inlet

times on the order of 10 to 30 min with good resolution.

filters are attached to the liquid-carrying Teflon tubing

Because smaller sample volumes of usually 20 µl are nec-

to prevent any insoluble particles from being drawn to

essary to not exceed the capacity of these columns, detec-

the pump where they could cause check valve malfunc-

tors equipped with flow cells have been developed for

tion. As shown in Fig. 1, blending of the mobile phase

more sensitive and convenient detection of the separated

constituents in the proper ratio is accomplished by the

components. This description of HPLC is considered to

solenoid proportioning valves A, B, and C. By control-

be analytical in nature and will be the major emphasis of ling the fraction of time each valve is opened using the

this article. However, preparative and microbore HPLC computer system through a digital-to-analog (DAC) in-

which bracket analytical HPLC with respect to flow rates, terface, a reproducible mobile phase made up of two or

sample size, and column dimensions will be briefly dis- three components can be formed in the mixing chamber.

cussed. Capillary HPLC and the relatively new technique, The volume of the mixing chamber should be kept small

capillary electrochromatography, will also be compared. to minimize gradient lag time at the column. The mixing

chamber, often magnetically stirred, contains a 2 µm frit

for final mobile phase filtration before it reaches the pump.

I. ANALYTICAL HPLC High-pressure mixing is an alternative method for gen-

eration of the desired mobile phase. The outlets of two

A block diagram for a typical instrument or high- or more HPLC pumps are connected into a mixing cham-

performance liquid chromatograph is shown in Fig. 1. ber. Basically, the solvents are mixed on the high-pressure

Each part of the chromatograph will be described in some side of the pumps. The composition of the desired mo-

detail with respect to analytical HPLC first. bile phase is dependent on the selected pumping speeds

of each pump, which are often computer controlled. The

A. Solvent Mixing resultant flow rate represents the combined output of the

individual pump flow rates. Although precise control of

The mobile phase reservoirs are generally screw-top

the gradient composition is possible using this system, the

plastic-coated glass bottles with inlet lines to allow for

expense of multiple pumps is a disadvantage.

degassing of the solvents for 10–15 min either by vacuum

or sparging with helium or both. A positive pressure of

B. Pump

helium should be maintained in the solvent bottles. De-

gassing is important to prevent gas bubbles from lodging The HPLC pump must meet several criteria. These are

in the pump, column, or the detector. On-line degassing (1) pumping capability up to 6000 psi, (2) pulseless