Page 23 - Energy from Toxic Organic Waste for Heat and Power Generation

P. 23

12 Energy from Toxic Organic Waste for Heat and Power Generation

Syngas

treatment

Raw Clean

Exhaust gases

syngas syngas

Biomass

Pyrolyzer

Post Char

combustor

Tar Syngas

Heat compressor

exchanger Reg

Rec

Flue gases

treatment

Air Gas turbine

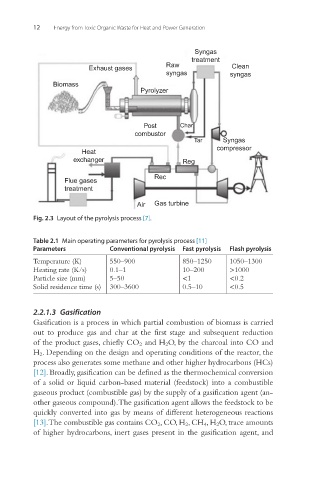

Fig. 2.3 Layout of the pyrolysis process [7].

Table 2.1 Main operating parameters for pyrolysis process [11]

Parameters Conventional pyrolysis Fast pyrolysis Flash pyrolysis

Temperature (K) 550–900 850–1250 1050–1300

Heating rate (K/s) 0.1–1 10–200 >1000

Particle size (mm) 5–50 <1 <0.2

Solid residence time (s) 300–3600 0.5–10 <0.5

2.2.1.3 Gasification

Gasification is a process in which partial combustion of biomass is carried

out to produce gas and char at the first stage and subsequent reduction

of the product gases, chiefly CO 2 and H 2 O, by the charcoal into CO and

H 2 . Depending on the design and operating conditions of the reactor, the

process also generates some methane and other higher hydrocarbons (HCs)

[12]. Broadly, gasification can be defined as the thermochemical conversion

of a solid or liquid carbon-based material (feedstock) into a combustible

gaseous product (combustible gas) by the supply of a gasification agent (an-

other gaseous compound). The gasification agent allows the feedstock to be

quickly converted into gas by means of different heterogeneous reactions

[13]. The combustible gas contains CO 2 , CO, H 2 , CH 4 , H 2 O, trace amounts

of higher hydrocarbons, inert gases present in the gasification agent, and