Page 289 - Engineering Plastics Handbook

P. 289

Liquid Crystal Polymer (LCP) 251

Instability in material feed

Low viscosity Pellet

Screw

Backflow

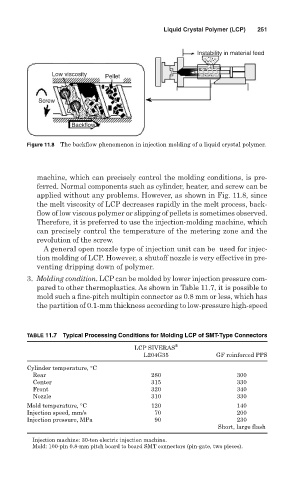

Figure 11.8 The backflow phenomenon in injection molding of a liquid crystal polymer.

machine, which can precisely control the molding conditions, is pre-

ferred. Normal components such as cylinder, heater, and screw can be

applied without any problems. However, as shown in Fig. 11.8, since

the melt viscosity of LCP decreases rapidly in the melt process, back-

flow of low viscous polymer or slipping of pellets is sometimes observed.

Therefore, it is preferred to use the injection-molding machine, which

can precisely control the temperature of the metering zone and the

revolution of the screw.

A general open nozzle type of injection unit can be used for injec-

tion molding of LCP. However, a shutoff nozzle is very effective in pre-

venting dripping down of polymer.

3. Molding condition. LCP can be molded by lower injection pressure com-

pared to other thermoplastics. As shown in Table 11.7, it is possible to

mold such a fine-pitch multipin connector as 0.8 mm or less, which has

the partition of 0.1-mm thickness according to low-pressure high-speed

TABLE 11.7 Typical Processing Conditions for Molding LCP of SMT-Type Connectors

LCP SIVERAS ®

L204G35 GF reinforced PPS

Cylinder temperature, °C

Rear 280 300

Center 315 330

Front 320 340

Nozzle 310 330

Mold temperature, °C 120 140

Injection speed, mm/s 70 200

Injection pressure, MPa 90 230

Short, large flash

Injection machine: 30-ton electric injection machine.

Mold: 100-pin 0.8-mm pitch board to board SMT connectors (pin-gate, two pieces).