Page 165 - Enhanced Oil Recovery in Shale and Tight Reservoirs

P. 165

Gas flooding compared with huff-n-puff gas injection 149

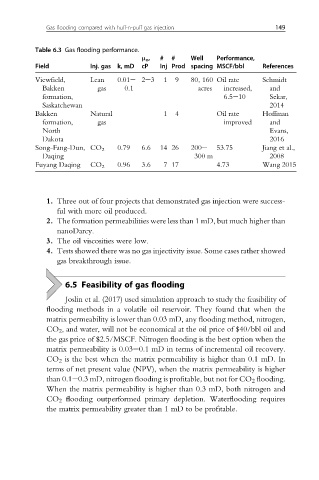

Table 6.3 Gas flooding performance.

m o , # # Well Performance,

Field Inj. gas k, mD cP Inj Prod spacing MSCF/bbl References

Viewfield, Lean 0.01e 2e3 1 9 80, 160 Oil rate Schmidt

Bakken gas 0.1 acres increased, and

formation, 6.5e10 Sekar,

Saskatchewan 2014

Bakken Natural 1 4 Oil rate Hoffman

formation, gas improved and

North Evans,

Dakota 2016

0.79 6.6 14 26 200e 53.75 Jiang et al.,

Song-Fang-Dun, CO 2

Daqing 300 m 2008

Fuyang Daqing CO 2 0.96 3.6 7 17 4.73 Wang 2015

1. Three out of four projects that demonstrated gas injection were success-

ful with more oil produced.

2. The formation permeabilities were less than 1 mD, but much higher than

nanoDarcy.

3. The oil viscosities were low.

4. Tests showed there was no gas injectivity issue. Some cases rather showed

gas breakthrough issue.

6.5 Feasibility of gas flooding

Joslin et al. (2017) used simulation approach to study the feasibility of

flooding methods in a volatile oil reservoir. They found that when the

matrix permeability is lower than 0.03 mD, any flooding method, nitrogen,

CO 2 , and water, will not be economical at the oil price of $40/bbl oil and

the gas price of $2.5/MSCF. Nitrogen flooding is the best option when the

matrix permeability is 0.03e0.1 mD in terms of incremental oil recovery.

CO 2 is the best when the matrix permeability is higher than 0.1 mD. In

terms of net present value (NPV), when the matrix permeability is higher

than 0.1e0.3 mD, nitrogen flooding is profitable, but not for CO 2 flooding.

When the matrix permeability is higher than 0.3 mD, both nitrogen and

CO 2 flooding outperformed primary depletion. Waterflooding requires

the matrix permeability greater than 1 mD to be profitable.