Page 49 - Environmental Control in Petroleum Engineering

P. 49

Drilling and Production Operations 37

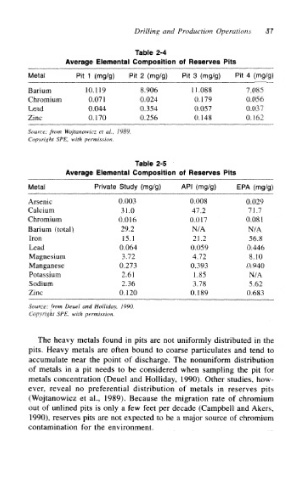

Table 2-4

Average Elemental Composition of Reserves Pits

Metal Pit 1 (mg/g) Pit 2 (mg/g) Pit 3 (mg/g) Pit 4 (mg/g)

Barium 10.119 8.906 11.088 7.085

Chromium 0.071 0.024 0.179 0.056

Lead 0.044 0.354 0.057 0.037

Zinc 0.170 0.256 0.148 0.162

Source: from Wojtanowicz et at., 1989.

Copyright SPE, with permission

Table 2-5

Average Elemental Composition of Reserves Pits

Metal Private Study (mg/g) API (mg/g) EPA (mg/g)

Arsenic 0.003 0.008 0.029

Calcium 31.0 47.2 71.7

Chromium 0.016 0.017 0.081

Barium (total) 29.2 N/A N/A

Iron 15.1 21.2 56,8

Lead 0.064 0.059 0.446

Magnesium 3.72 4.72 8.10

Manganese 0.273 0.393 0.940

Potassium 2.61 1.85 N/A

Sodium 2.36 3.78 5.62

Zinc 0.120 0.189 0.683

Source: from Deuel and Holliday, 1990.

Copyright SPE, with permission.

The heavy metals found in pits are not uniformly distributed in the

pits. Heavy metals are often bound to coarse particulates and tend to

accumulate near the point of discharge. The nonuniform distribution

of metals in a pit needs to be considered when sampling the pit for

metals concentration (Deuel and Holliday, 1990). Other studies, how-

ever, reveal no preferential distribution of metals in reserves pits

(Wojtanowicz et al., 1989). Because the migration rate of chromium

out of unlined pits is only a few feet per decade (Campbell and Akers,

1990), reserves pits are not expected to be a major source of chromium

contamination for the environment.